Why is winder efficiency so important to paper mill profitability?

In the paper industry, winder performance is a crucial factor – if not run at optimal speed, time, money, and resources are wasted, and it rapidly becomes a bottleneck for paper production. This also makes it difficult to meet customer requirements for paper quality. Automated winder target control ensures winder performance to make the entire paper production process more efficient.

There are various ways of creating value in the paper and board industry. Low cost however is and will remain, a critical factor for high financial performance. One of the important themes that pulp and paper products CEOs consider, is finding the next level of cost optimization. The current energy crisis and changes in the market are forcing a re-think of how the industry’s operations are run. The importance of production efficiency increases even more, in these challenging economical times.

In the paper industry, winder performance is a crucial factor – if not run at optimal speed, time, money, and resources are wasted, and it rapidly becomes a bottleneck for paper production. This also makes it difficult to meet customer requirements for paper quality. Automated winder target control ensures winder performance to make the entire paper production process more efficient.

To improve paper mill productivity, three elements are especially important for automated winder operation and target control. These are presented in the following.

Paper defects detected and located accurately in advance

Quality and efficiency are those two fundamental criteria that paper mills highlight whenever they are screening out a suitable solution to optimize their winder performance and paper web monitoring solutions. Various types of defects may occur in the paper web, that can lead to different levels of errors with the paper machine reeler and winder. Identifying these effects on time and locating them accurately is what Procemex is known for worldwide. We have developed world-leading web inspection and monitoring technology, that enables paper mills to accurately detect and locate paper web defects and take action accordingly.

In the converting phase, the most critical defects are those that cause a web break on the winder. Procemex has prevented thousands of web breaks in paper machines and winders, improving overall production line efficiency for our customers. We specialize in detecting even the most difficult defects on the paper web and paper edges. In some cases, the edges get curled or the paper web edges flutter heavily, making web inspection extremely difficult. To avoid this, we have developed mechanical edge guides that act like bridges helping the paper web run smoothly.

Another problem that our customers have sometimes faced is that the paper web moves cross-directionally. Keeping on track with the paper defects and locating these defects even in the most challenging circumstances, all the way to the customer roll level is extremely important.

With Procemex solutions, paper mills can handle their customer claims more efficiently, as the defects can be smoothly located all the way to the customer roll level. And in many cases, the paper defects have been located and removed before they can reach the final product. To sum up, efficient web inspection solutions not only reduce costs, but also improve product quality, ensure the paper mill’s end customer satisfaction, and facilitate sustainable use of resources in paper mills.

Paper defects removed effectively

For a winder to operate as efficiently as possible, there are two main requirements. First, the operators need a clear defect map with the length, width, and type of defects accurately marked. And second, there must be a clear understanding of the nature of the defect. Some defects need to be completely removed, while others only require reducing the winder operation speed.

Optimally performing Web Inspection system brings a solution for both these requirements. Based on accurate knowledge of the machine’s directional and cross-directional defect location, operators can make educated decisions, about whether to run the winder at full speed, slow it down, crawl, or stop the winder for patching the defect. These decisions can be made either manually by the operators or the process can be automated. Highly automated winder operation enables the winder speed to be optimized in every running condition.

Increased production line throughput

Running the winder at optimum speed and preventing web breaks are essential for process efficiency, saving on cost, time, and resources. When our customers can more accurately detect the source of paper web defects, they have been able to eliminate their root causes from the earlier production phases.

Investing in winder efficiency is now a priority for paper mills worldwide. Thanks to the savings and increased profitability that they make possible, Procemex web inspection and web monitoring systems in effect pay for themselves in a short time. Paper mills all over the world that have invested in Procemex systems have saved between 5 and 15 million euros annually. These savings are the result by:

- avoiding winder web breaks and the consequent costs

- energy savings

- the winder can be run at optimal speed, taking full advantage of optimized slowdowns and accelerations

- the root causes of paper web defects can be traced and eliminated from the preceding production process phases

- enhanced product quality leads to improved customer satisfaction

How optimally are your paper mill’s winders running? We at Procemex are dedicated to finding solutions to make every winder operate at its best.

You might also be interested in

Web Inspection

Procemex Web Inspection System provides continuous detection of all paper defects. Web Inspection system can be seamlessly integrated to Procemex Web Monitoring System.

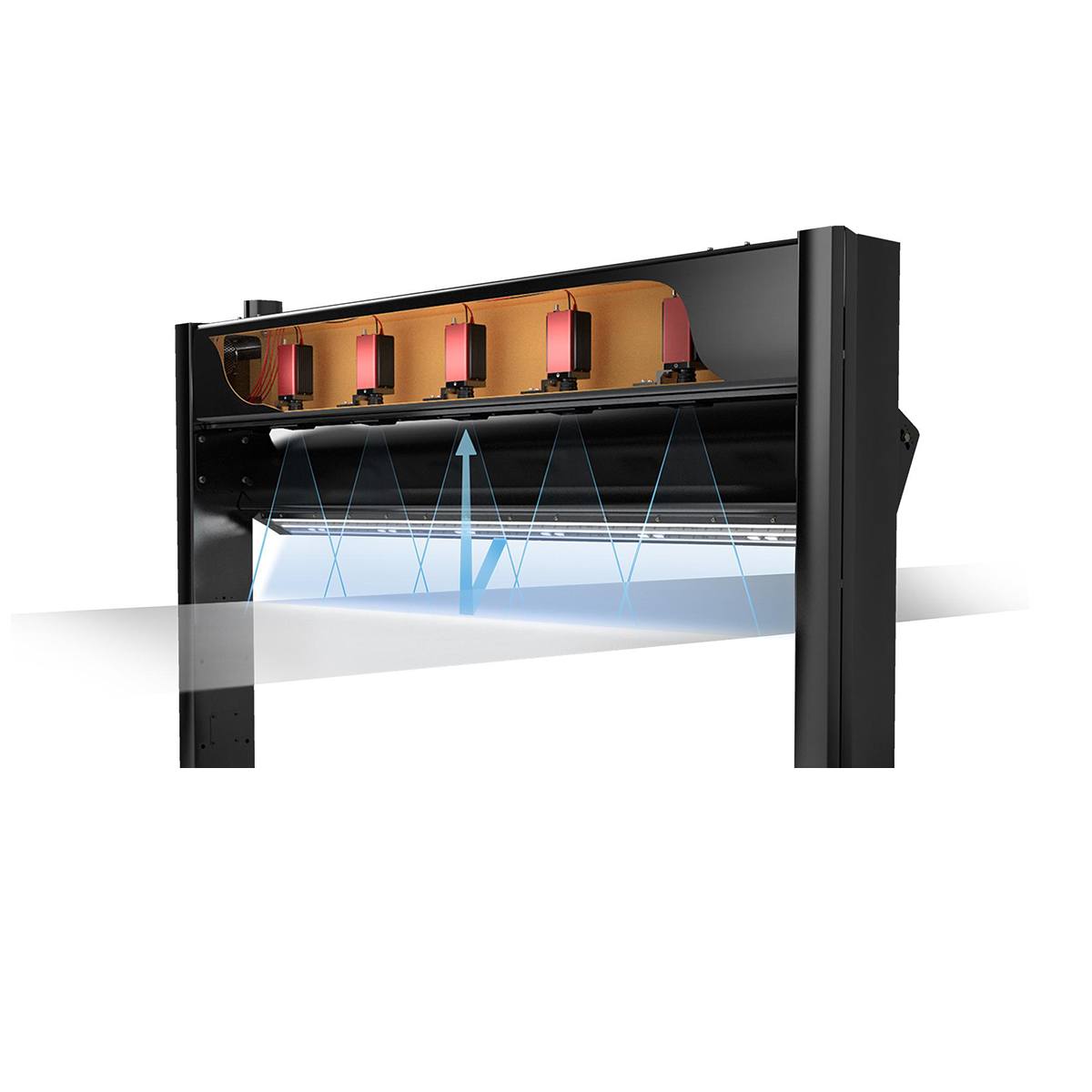

The world leading Web Inspection technology enables highest level defect detection with Photographic Imaging Quality. Powerful strobing LED lighting eliminate blur and produce photographic image quality.

The applications range today from coated box board to coated paper, magazine paper, newsprint, tissue and liner board. In addition, utilization of auto-shutter of a smart camera design is preferred amongst specialty paper makers for its wide range of detection capabilities.

Success Stories

Explore the collection of our Success Stories where we proudly showcase the transformative journeys of our clients who have harnessed the power of Procemex solutions to revolutionize their processes.

Explore firsthand accounts of how our cutting-edge technologies have enhanced efficiency, optimized processes, and elevated overall performance. From pulp and paper to printing and beyond. Join us on a journey of innovation and excellence.