Web Monitoring System for web break root cause analyzing

Procemex Web Monitoring Cameras along the production lines provide additional eyes for operators and clarify what happened during the milliseconds when a web break took place. With sufficient number of cameras in the right locations, the cameras provide required accuracy and clarity about the root cause of an event. Additionally, integration with Web Inspection reduces downtime, helps the operators in handling production quality, and production efficiency issues with the help of the systems’s smart analysis tools.

Full Set of Analysis Tools for Results

Procemex has full set of analysis tools for paper mill operators for handling the web break issues. Our Web Monitoring System assists operators in handling all production quality, and production efficiency issues with the systems’s advanced analysis tools.

- Full width visibility at wet end

- Superior resolution with 12 MPix smart camera technology

- Unique Wet End Pinhole Frame covers full machine width

- Operators focus on trouble-shooting in right areas

- Paper and fabrics related issue covered

- Trouble-shooting tools for moisture issues with Procemex Thermal Imaging Camera

- Defects and root causes identified quickly through elimination method

- More efficient process

- Less paper quality issues

- Reduced reaction times

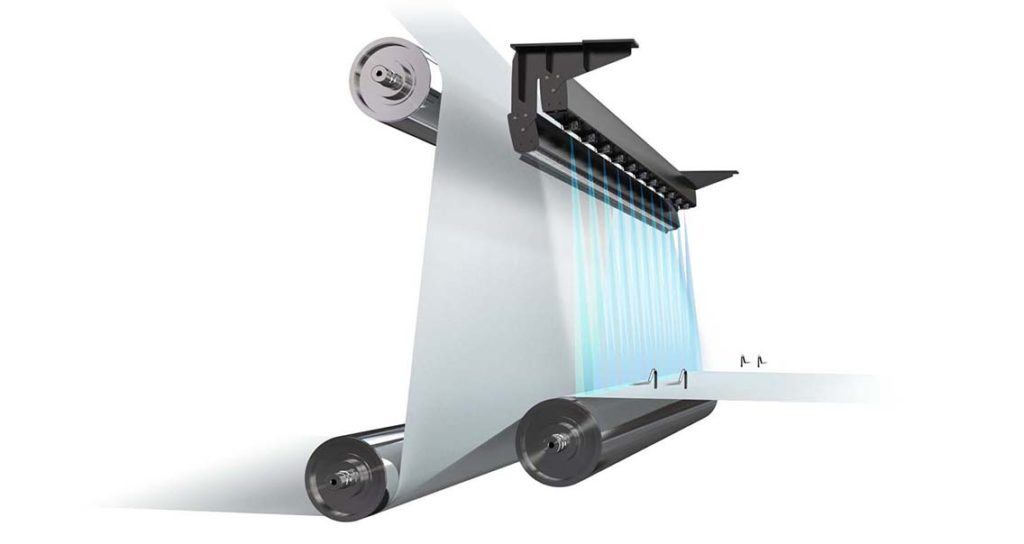

ProClean Pinhole Technology Keeps Cameras Clean

The challenge to keep the web break cameras clean is an everyday reality in all board and paper mills. Dirt in the camera’s protection window make the images dark and fuzzy. The new Procemex ProClean pinhole technology guarantees that cameras stay clean 24/7 and provide sharp and clear images for operators to monitor paper defects and root causes of web breaks.

Web monitoring cameras are kept clean under harsh wet end conditions with the aid of instrument air flow. The air is blown through a 5 mm hole in front of the camera housing. As the air flow speeds up when passing the pinhole it forms a strong protection against dirt and prevents water and dirt entering the housing. The housing has no protection window that could get dirty or wear out. The camera is equipped with a dedicated pinhole zoom lens capable of viewing through a very small hole.

Get sharp images from edge to edge without the need to clean the cameras.

AI-based Pick-Up Drop-Off Analysis

Detect potential problems before they become visible to traditional web monitoring system. By analyzing video footage in real-time, AI identifies and notifies operators of potential problems before they become visible to traditional web monitoring system.

- AI sees edge drops very efficiently. Much earlier than traditional web monitoring cameras.

- Helps to prevent web breaks very efficiently.

- Saves operators’ time

- AI analyses the videos real-time, pinpoints the important parts, and gives alerts to the operators

- The system summarizes the relevant events in a quick and easy-to-review format. Events captured over the weekend can be reviewed in less than a minute.

Lights for Web Monitoring

The lights for Web Monitoring are cooled to meet fire safety requirements and Synchronized with the system.

Procemex uses LED strobe lights that are synchronized with AC sync with an ambient illumination to prevent a fade-in, fade-out effect from happening.

The latest LED technology is enhanced with customer designed focusing lenses, and optimized use of power. There are several light patterns available suitable for different locations.

Procemex ECO LED light has indirect cooling unit, that can use instrument air or water. The benefit of indirect cooling is that there is no instrument air inside the light, and that there is no possibility for over-pressurizing the housing and causing the protection window to explode.

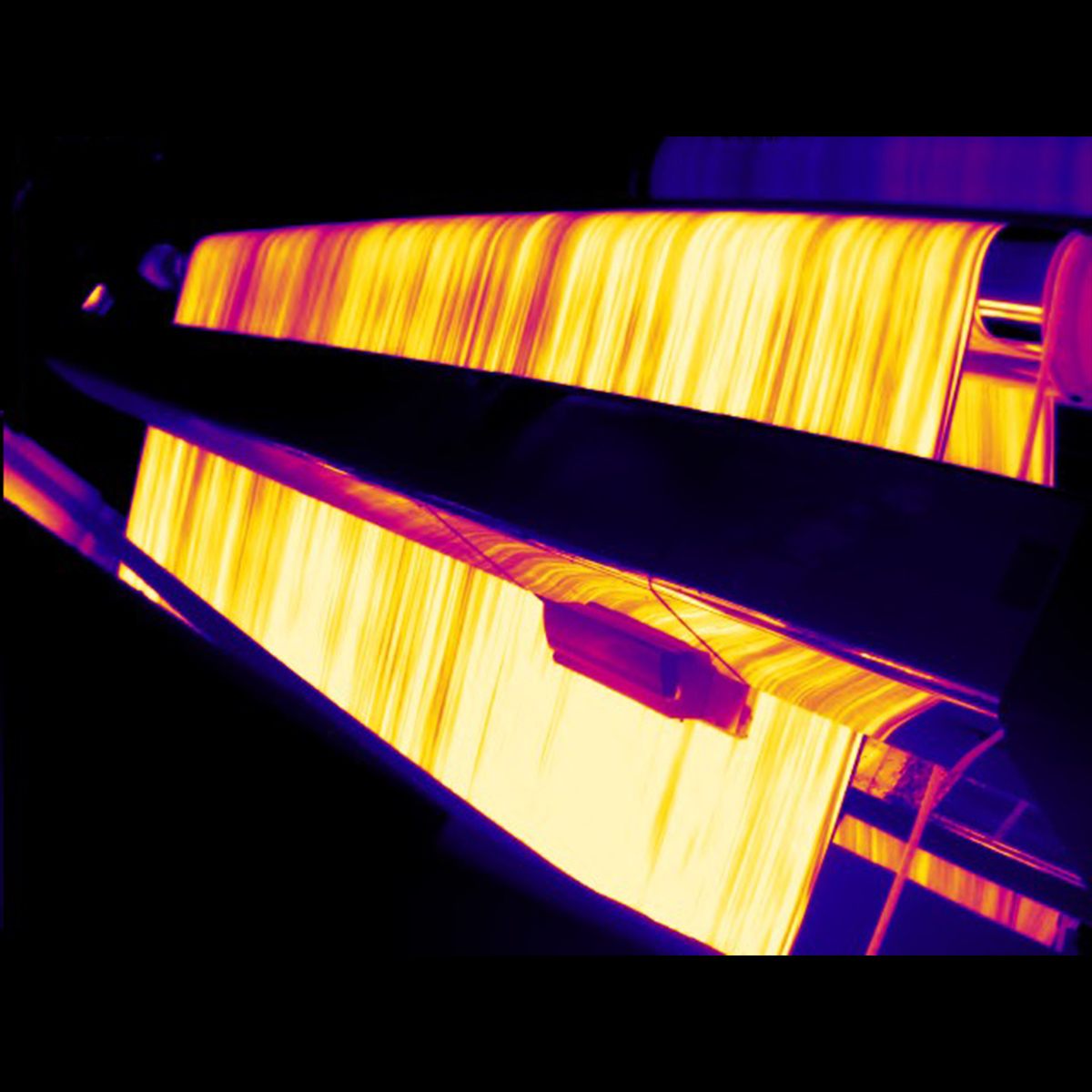

Trace paper defects with Procemex Infrared Thermal Smart Camera Technology

Procemex Infrared Thermal Smart Camera offers enhanced visibility for detecting defects in previously challenging areas, particularly those concealed by steam and fog.

For mills facing issues in areas where traditional web monitoring cameras falter due to steam, the Procemex Infrared Thermal Camera presents an ideal solution.

The Importance of Image Quality, Cleaning & Cooling

Image Quality and Importance of Maintenance

Lack of maintenance is the most typical reason for poor image quality. Read more, about our solutions for this problem.

Cooling & Cleaning in Harsh Paper Machine Environments

Air consumption plays an important role when figuring out new ways of saving energy at a paper mill. Read more, about our solutions for this challenge.

Forming and Press Section Web Monitoring and Web Inspection

Read more about different measurement geometry for monitoring web breaks, detecting and classifying surface defects and inspecting fabrics.