Web Inspection System for web defect detection

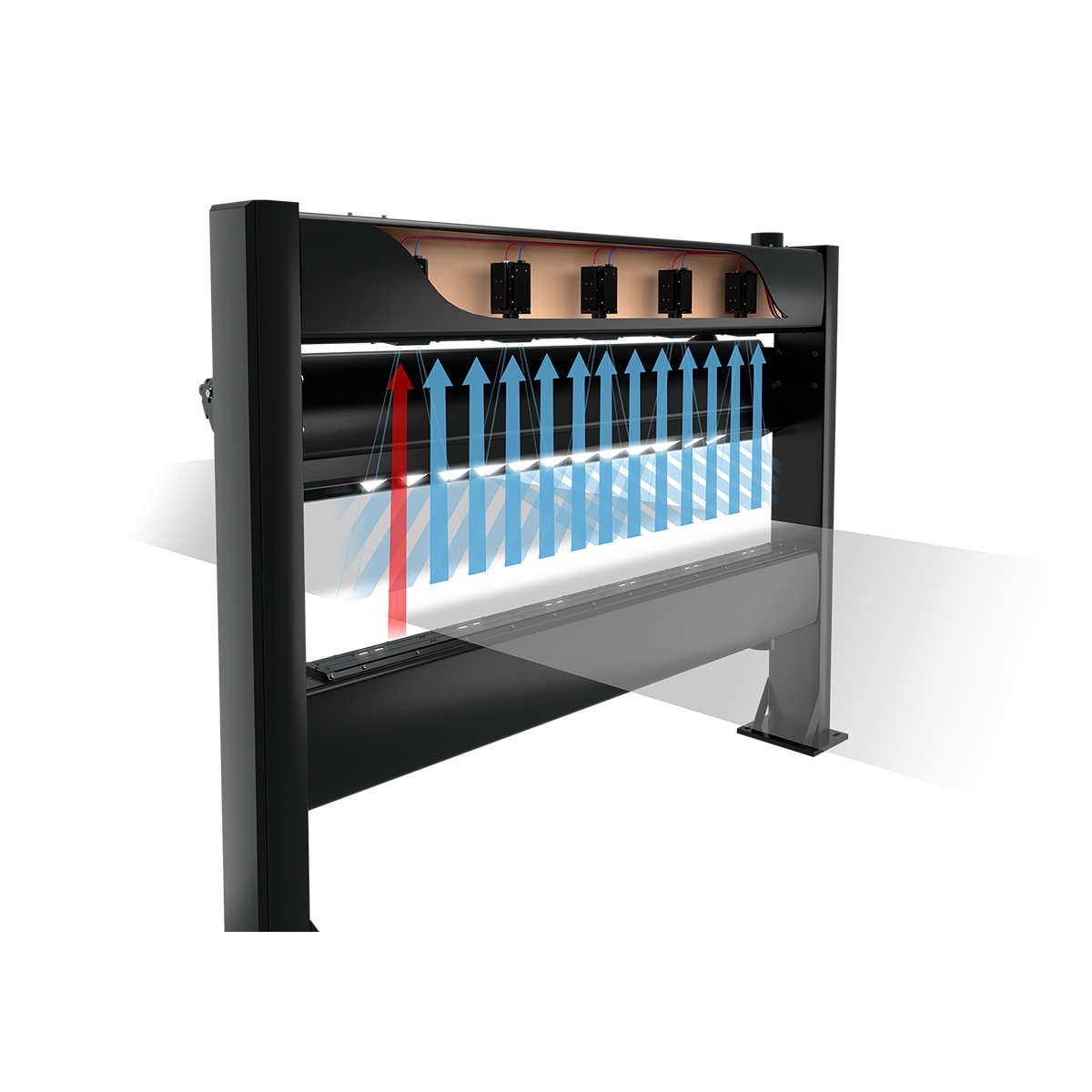

Procemex Paper Web Inspection System provides continuous detection of all paper defects. Web Inspection camera system can be seamlessly integrated to Procemex Paper Web Monitoring System.

The world leading Web Inspection technology enables highest level defect detection with Photographic Imaging Quality.

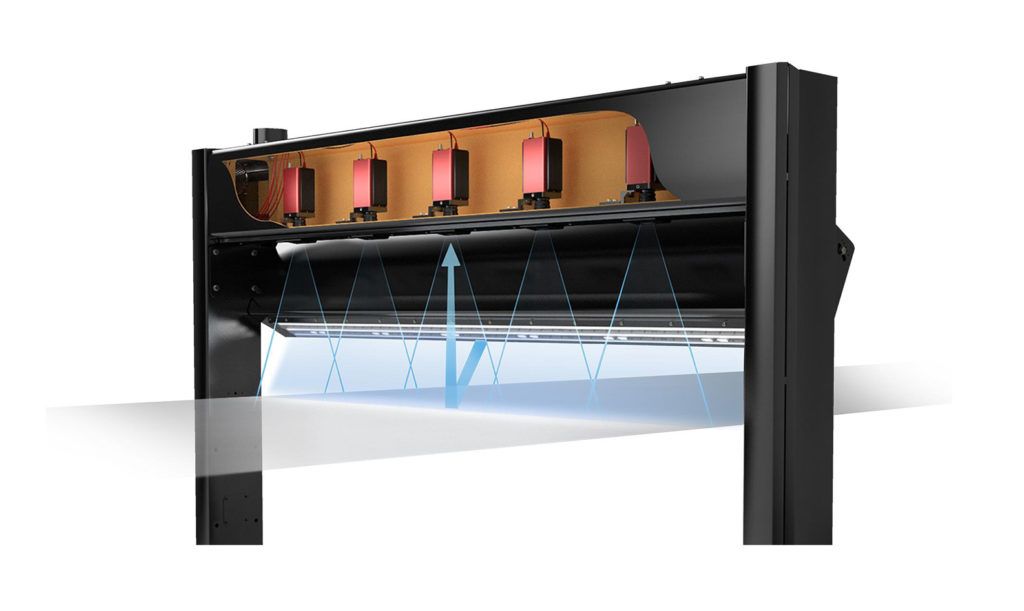

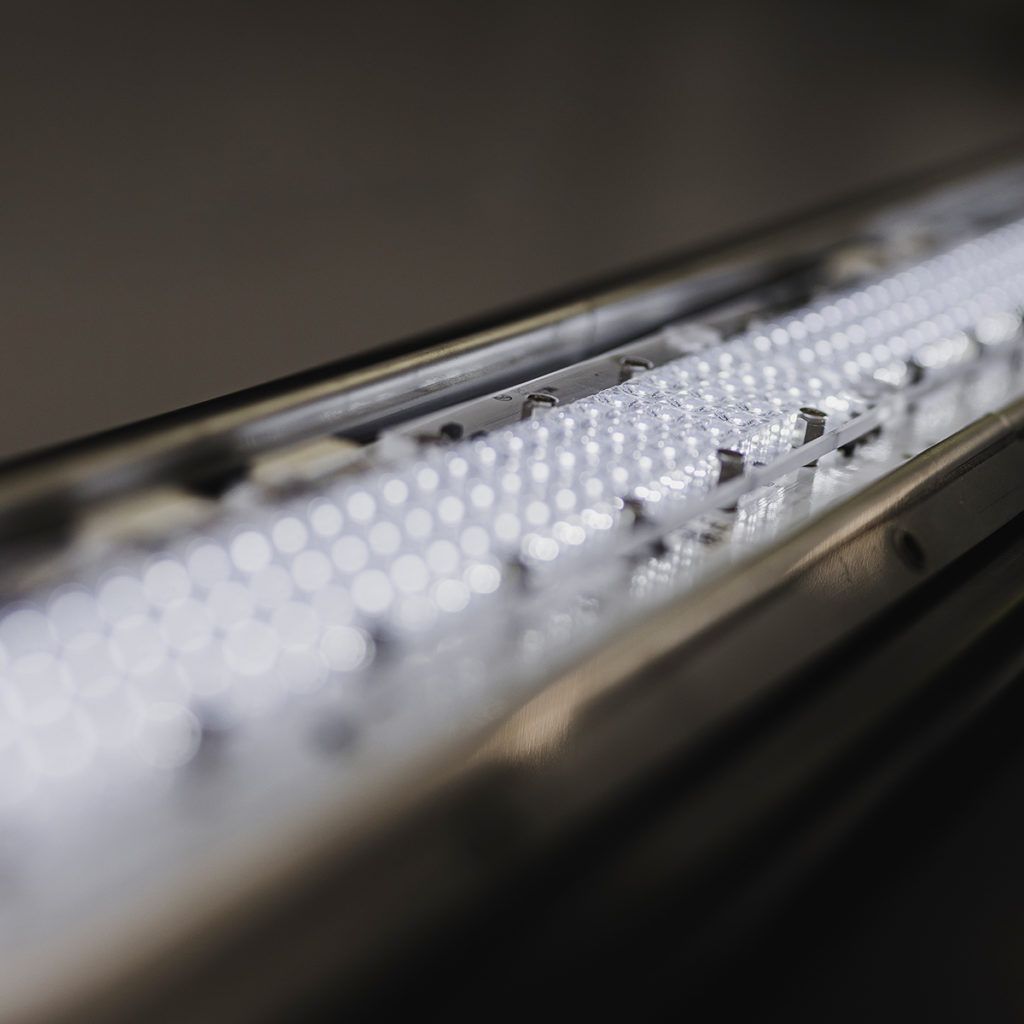

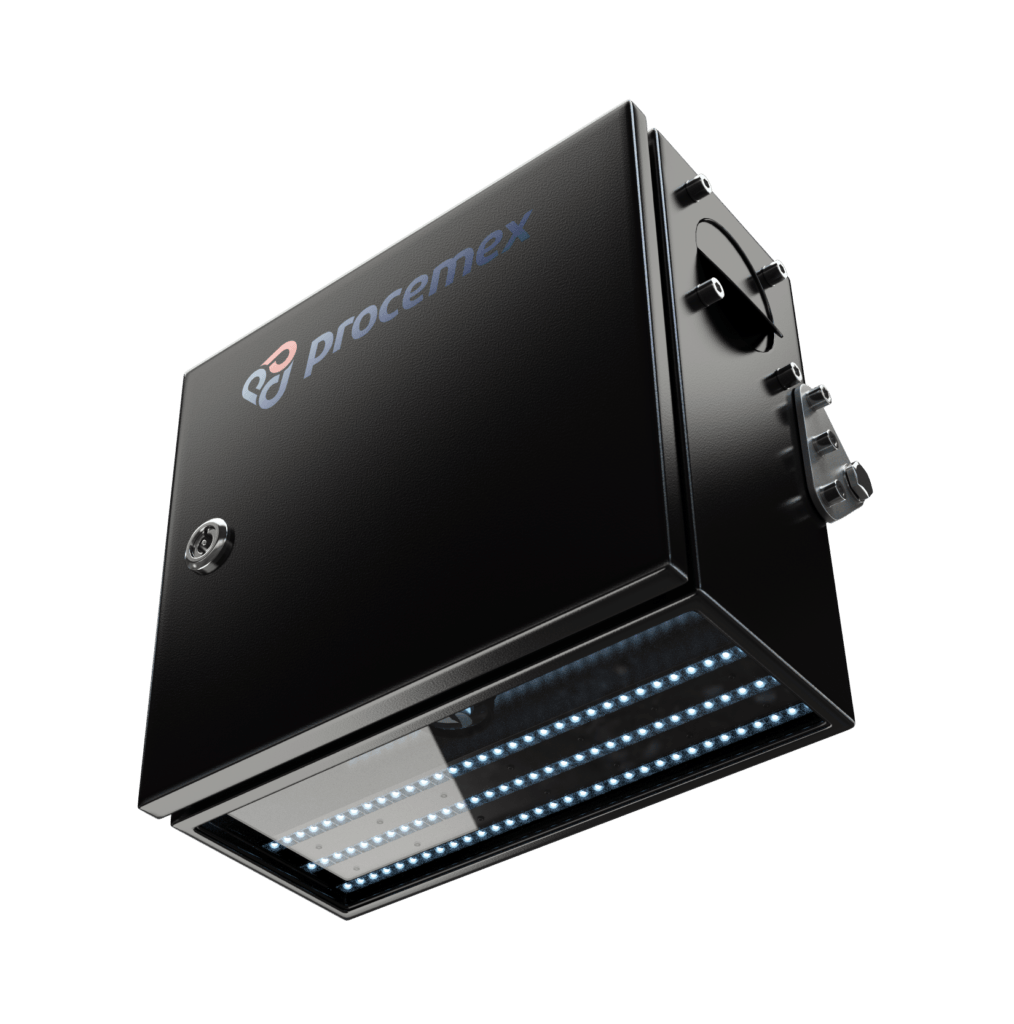

Powerful strobing LED lighting eliminate blur and produce photographic image

quality.

The applications range today from coated box board to coated paper, magazine paper, newsprint, tissue and liner board. In addition, utilization of auto-shutter of a smart camera design is preferred amongst specialty paper makers for its wide range of detection capabilities.

Web Inspection

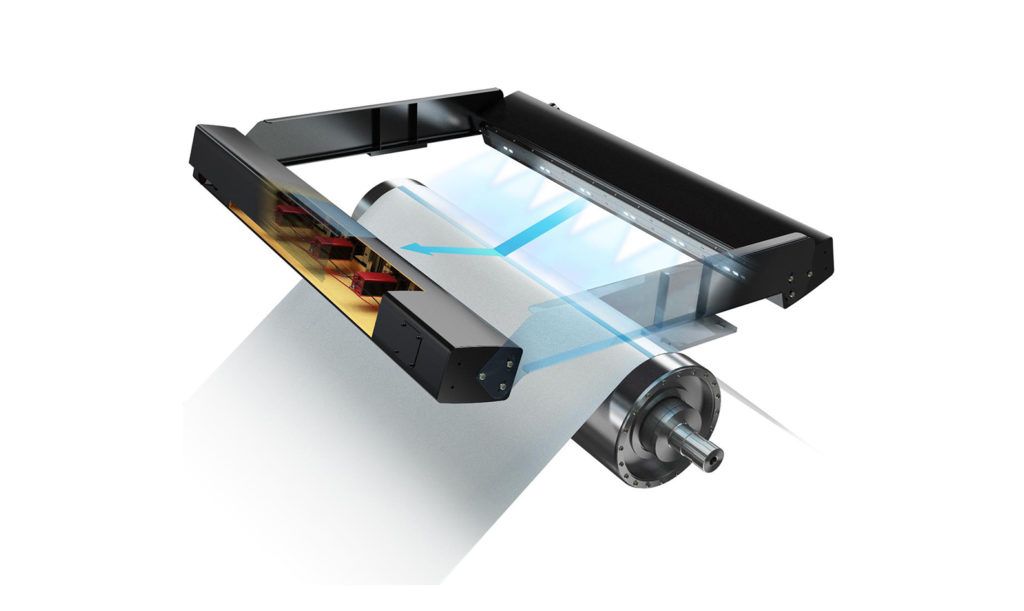

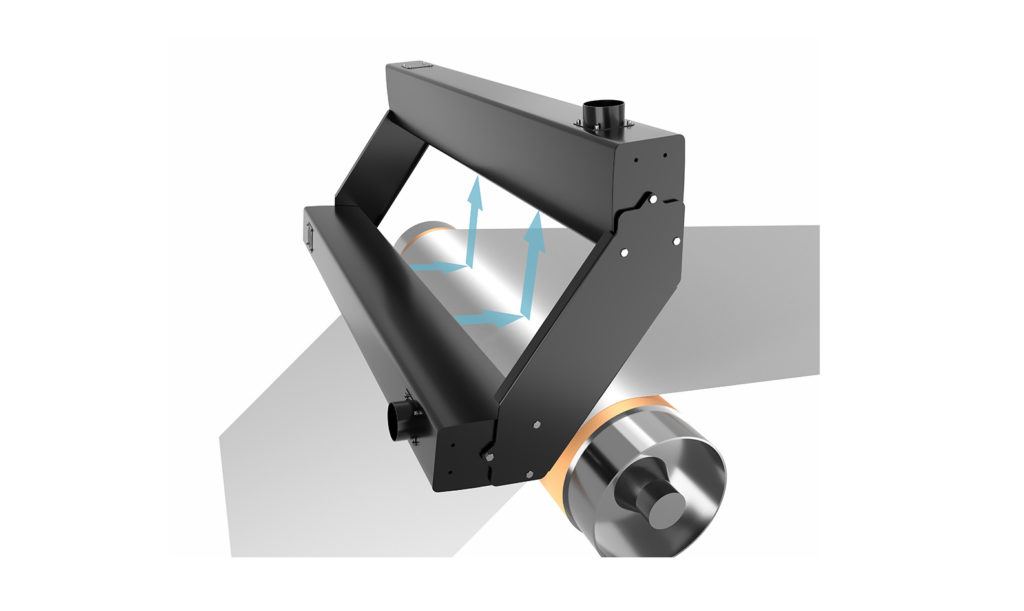

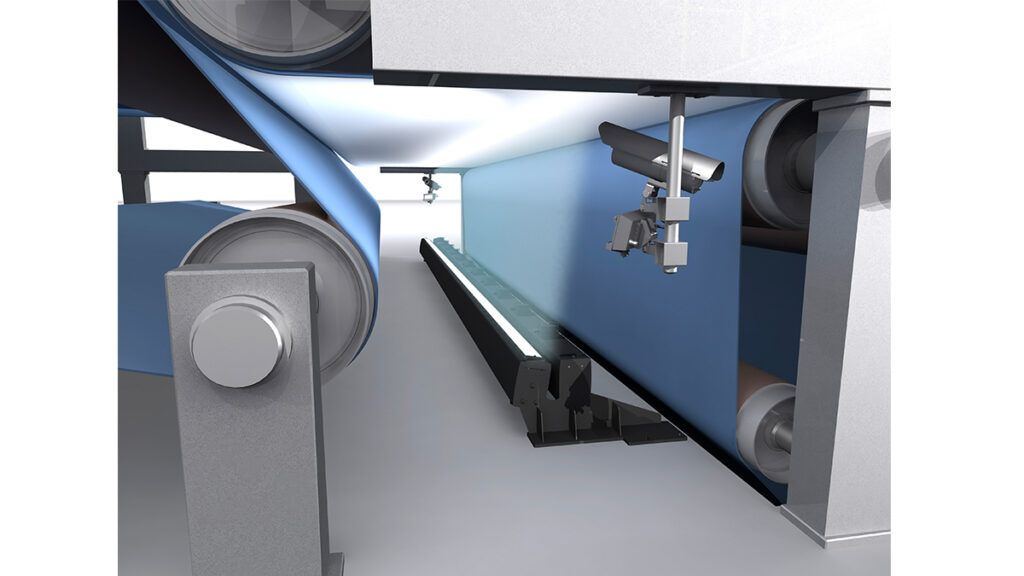

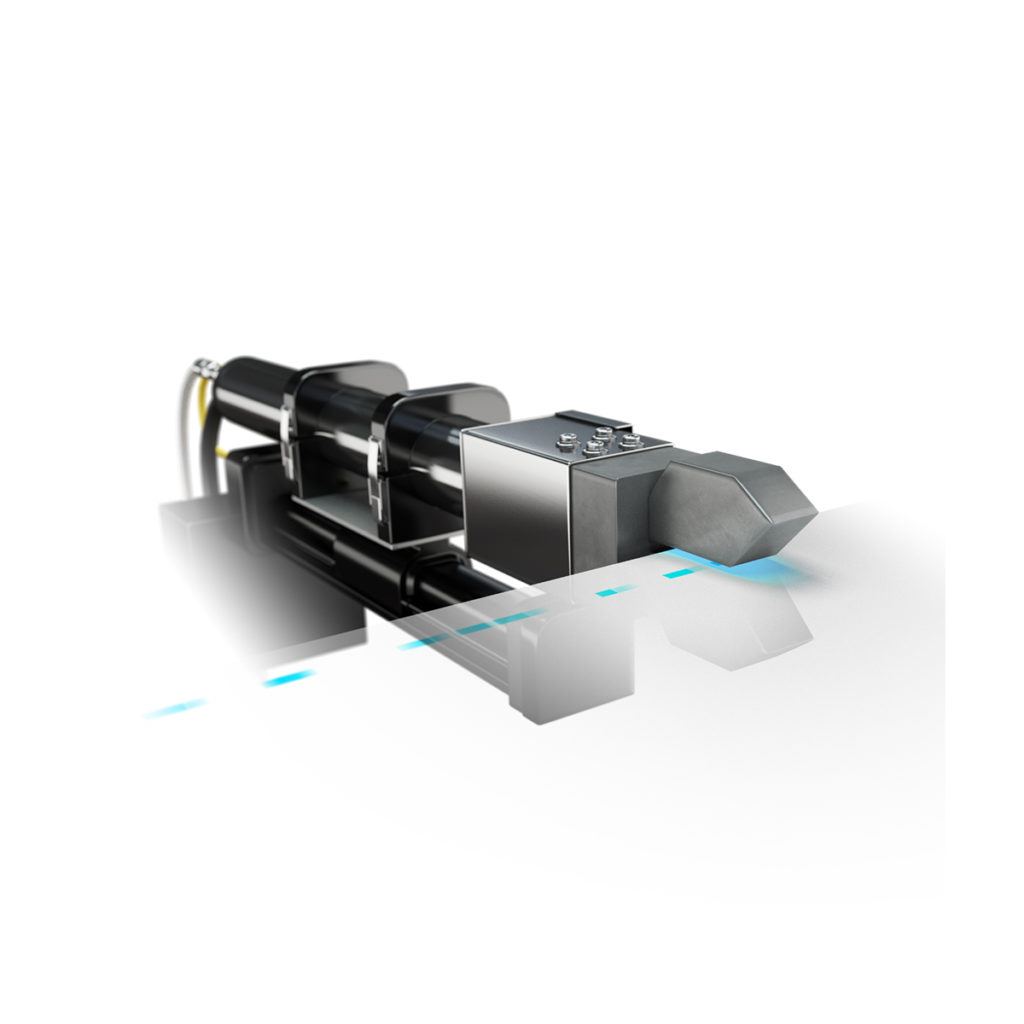

Measurement Geometries

Smart cameras Detect Paper web defects with Photographic Imaging Quality

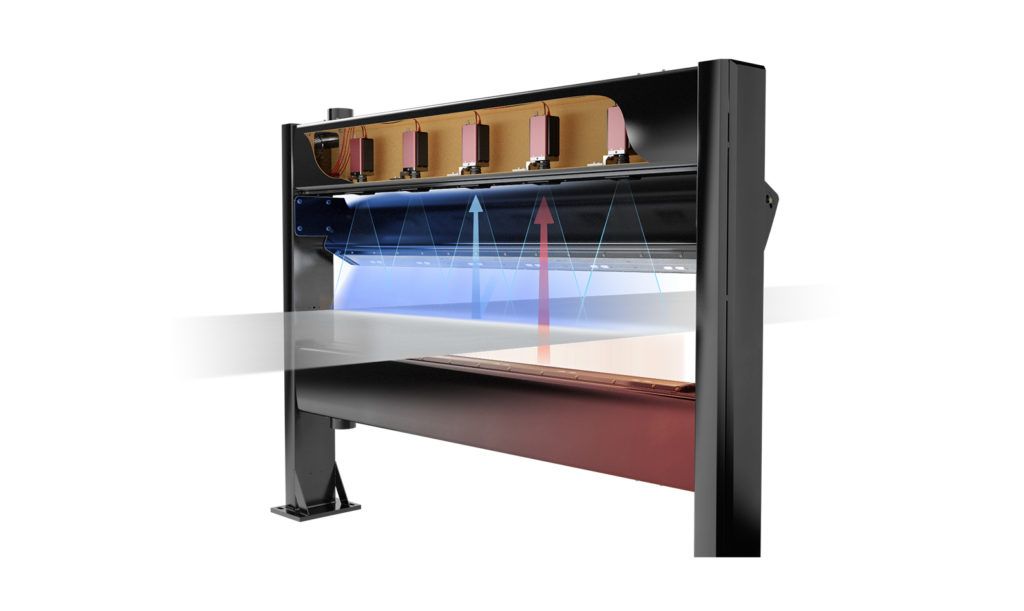

- Detection and classification in black&white or in color

- Smart Camera Autoshutter provides even exposure and illumination over multiple grades and shades of color. This enables fully automated grade settings even with hundreds of paper grades and color shades

- Square pixels, even with high speed processes, provide clarity for imaging

- Market leading 700 Million pixel per second data processing

- Strobing provides powerful illumination peak to stop the web movement, eliminate blur and produce photographic image quality

- Industry leading camera sensor light sensitivity and image bit depth

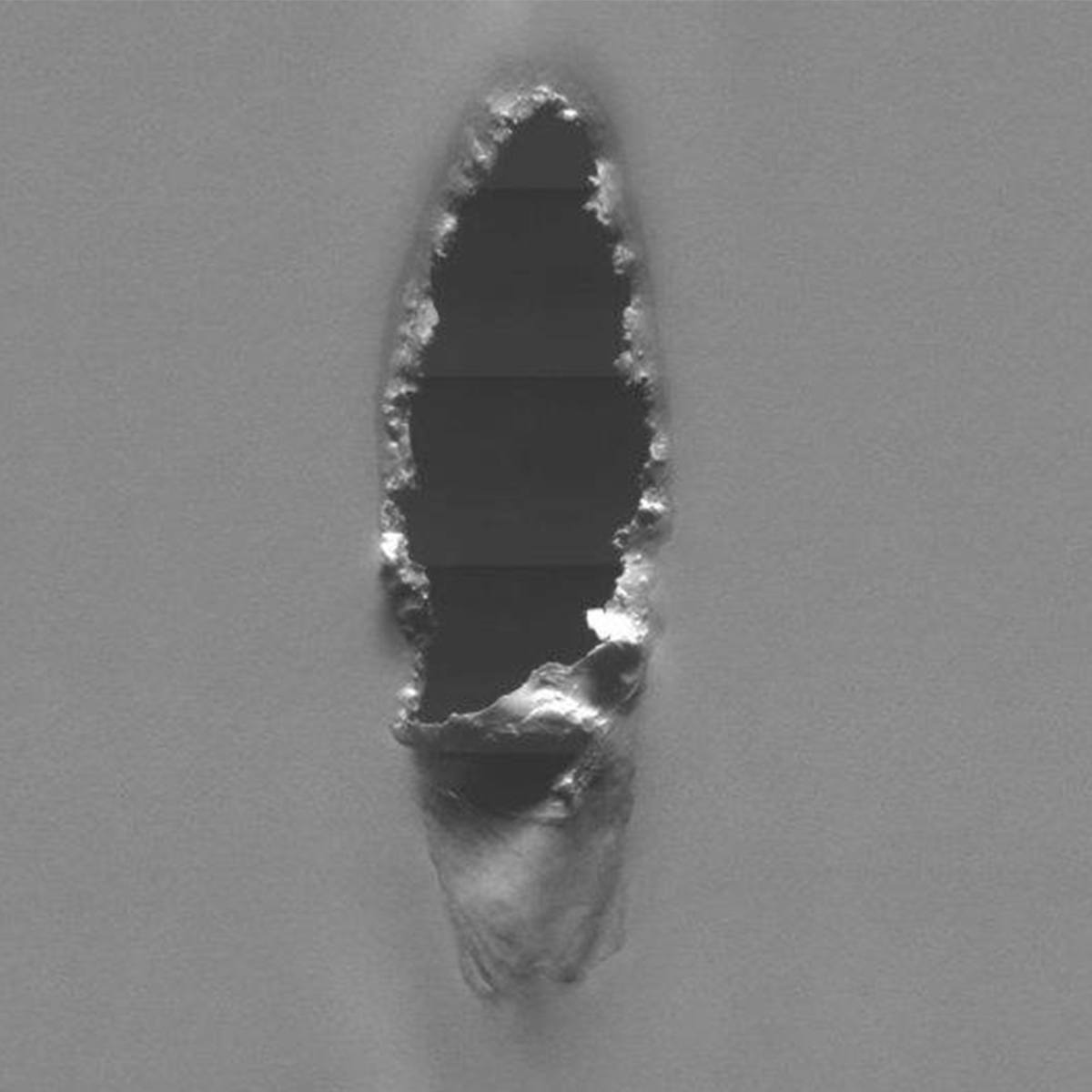

Defect Classification

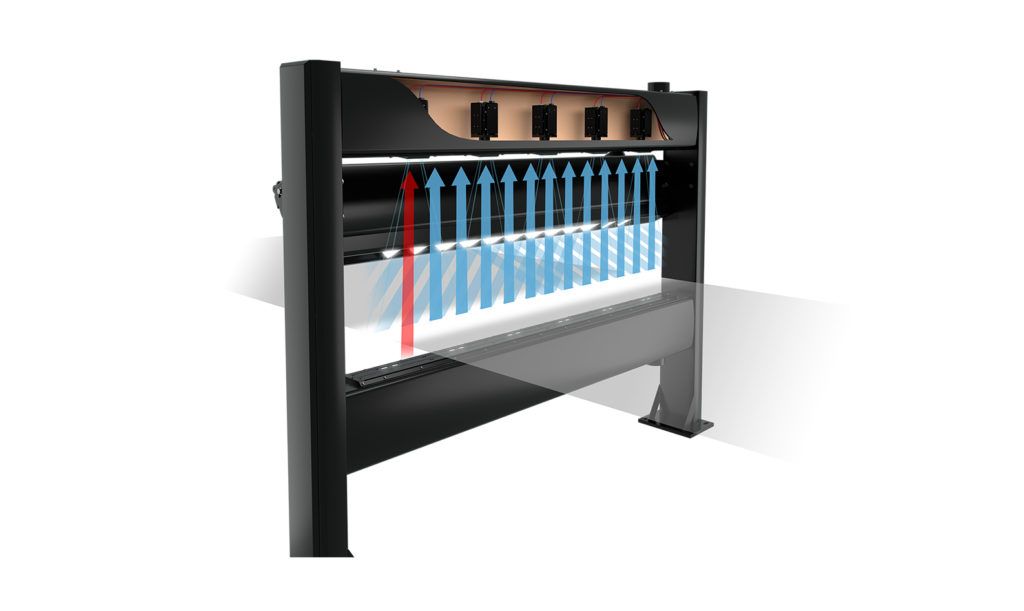

Pre-classification inside Procemex Smart Camera allows instantaneous paper quality classification for first level defects.

- Pre-classification is made inside Procemex Smart Cameras

- Classification based on color information

- Real-time outputs from first level defects

- Post-classification beyond single inspection frame measurement utilizing all data available for the most accurate classification

- Alternating illumination provides more information for the post-classification engine, increasing the benefits of the Smart Camera technology

- Advanced Classification utilizing our tools for developing or acquiring best fit traditional and neural network classification algorithms

Multi-frame camera imaging providing higher quality images to the classification engine and increasing accuracy over antiquated line-scan technology.

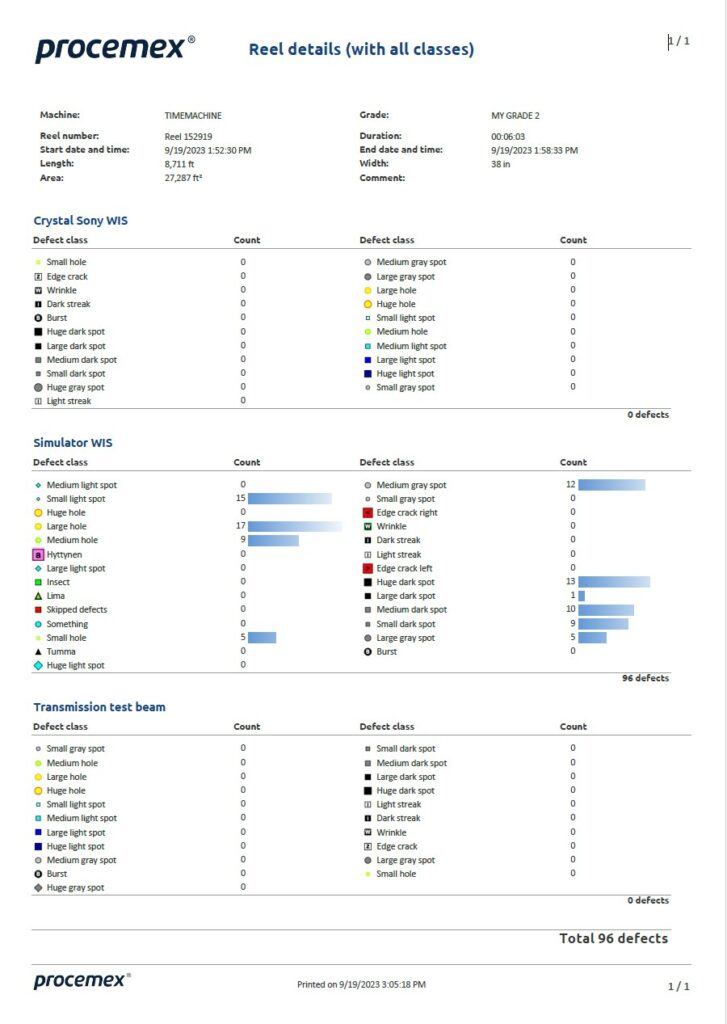

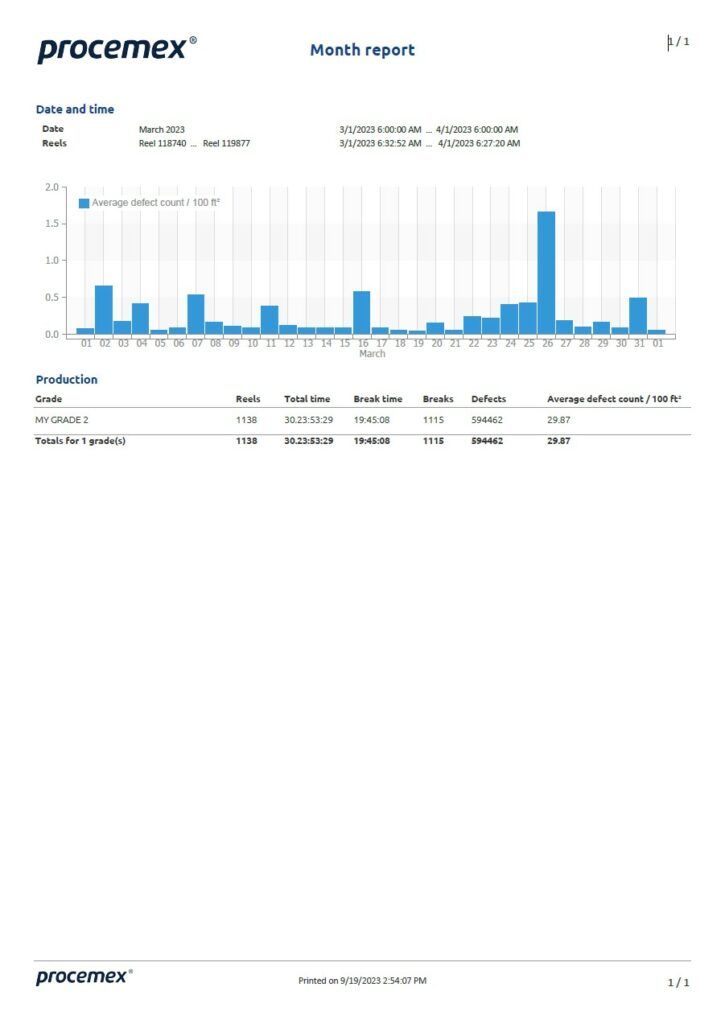

Quickly Create, Customize, and Export Inspection Reports

Send paper defect samples for our testing team

To better understand how our Web Inspection system recognizes and analyzes defects on your paper, we encourage you to send us a paper defect sample for analysis.

Our experienced testing team will conduct a comprehensive WIS analysis once your samples arrive, providing you with valuable insights that will help you assess the suitability of our solutions in your mill’s unique production environment.