AI Enhanced Dryline Analysis

With the help of smart Dryline Analysis the machine operators can keep the dryline in its optimal place leading to enhanced product quality, reduced use of raw materials, and energy savings.

Innovative camera-based Dryline Analysis helps to identify paper profile problems accurately. With the help of smart Dryline Analysis the machine operators can keep the water line in it’s optimal place leading to enhanced product quality, reduced use of raw materials, and energy savings.

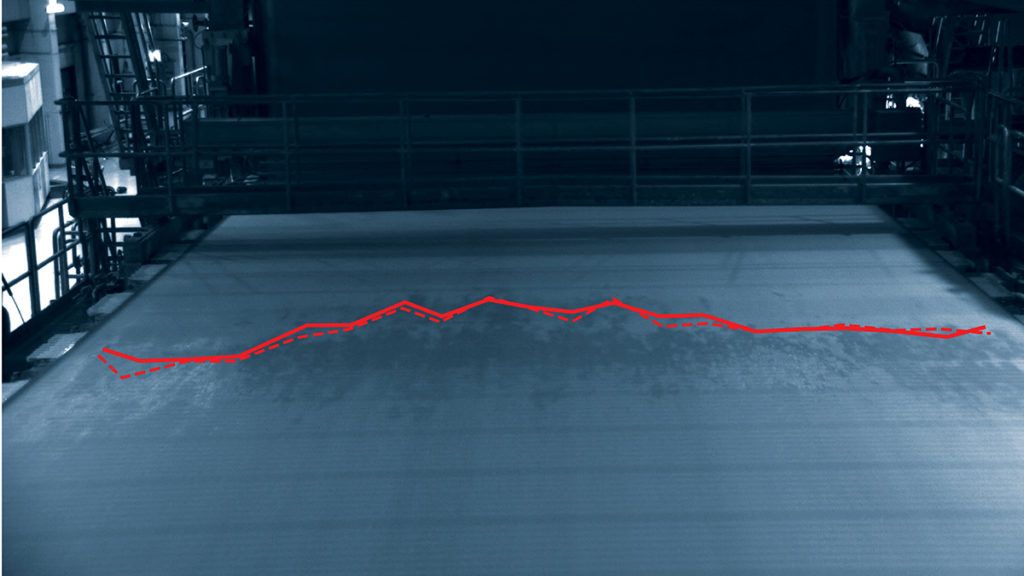

The Dryline Analysis pinpoints precisely and in real time wet line position and its CD profile variations indicating possible stock refining – and water removal issues.

The analysis provides a clearly visualized image making it is easy for operators to monitor the Dryline.

Dryline Data with images is stored in the Procemex One Platform web monitoring & web inspection system. With the help of the smart Dryline Analysis, the Dryline profile and location information can be collected efficiently for quality control purposes. The analyzed data can also be added to Web Inspection System defect map and data can be stored in ERP systems as well.