Automatic Threading Rope Monitoring

The Automatic Threading Rope Monitoring examines the condition of threading ropes and their expected lifetime 24/7. The Automatic rope condition monitoring prevents serious damages and expensive unplanned production shutdowns.

Significant cost savings

- Broken threading ropes cause expensive paper machine down time

- Installing a new rope requires shutting down the paper machine

- Threading a new rope through the machine without the old rope can take 12 to 24 hours depending on the damages

- Annual total cost caused by rope breaks can be > 0,5 M €

- Automatic Threading Rope Monitoring enables rope changes as preventive maintenance during scheduled down time

- Rope breaks are a safety hazard. They can cause severe damage to people and equipment.

Rope Condition Monitored 24/7

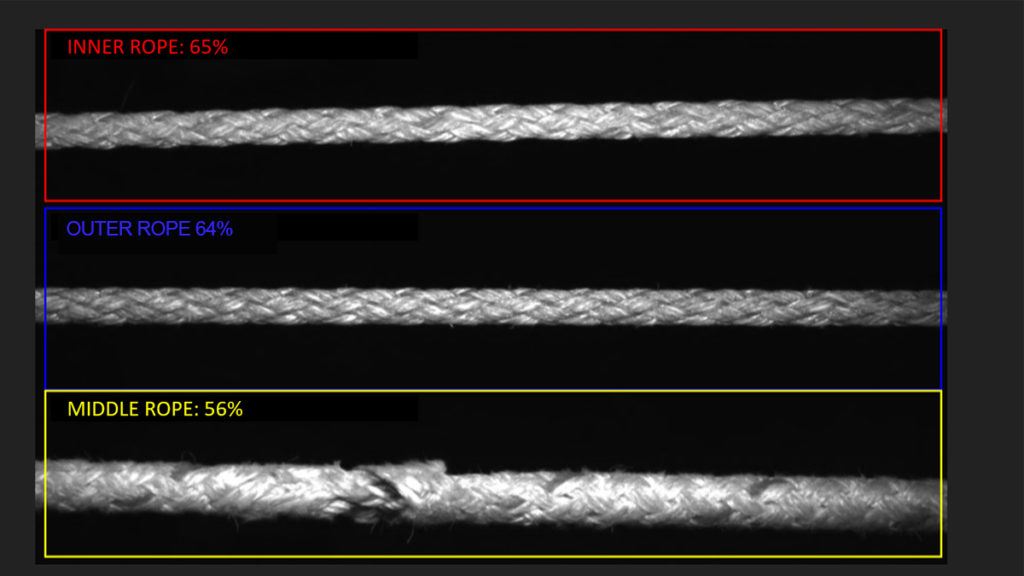

- Monitors threading rope’s condition and expected lifetime 24/7

- Increases the mill safety

- Helps to prevent:

- Unexpected rope & web breaks

- Unplanned machine shutdowns

- Optimizes threading rope change intervals

- Saves operators’ time

Success Stories

Success story

Metsä Board Äänekoski, Finland monitors Carrier Rope Condition 24/7

The latest functionality adopted by Metsä Board Äänekoski, Finald has been the Tail Threading Rope Condition Monitoring. The carrier ropes’ condition is continuously monitored with Procemex cameras utilizing cutting-edge AI-analysis technology. As a result, the threading rope changes can be conducted as preventive maintenance during scheduled machine shutdowns, reducing the number of unexpected and expensive web breaks and machine down times.

Nippon Dynawave Packaging: Superior Product Quality and Increased Uptime with Procemex Web Monitoring and Web Inspection System

BillerudKorsnäs Gruvön Mill: “We Are Really Happy to Run Procemex OnePlatform System”

Metsä Board Äänekoski: Higher Customer Satisfaction and Line Efficiency with Procemex Web Monitoring and Inspection System