Superior Tool for finding Root Causes of Web Breaks

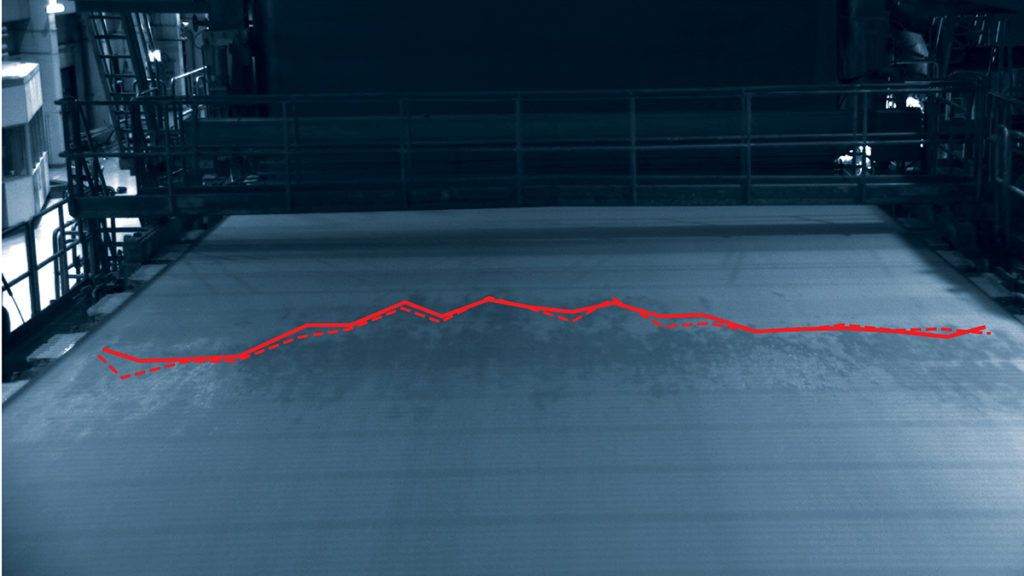

Snap, and it happens. A web break, that mixes up your planned paper production and every operator’s day plan. An event that pushes all other daily tasks aside. To avoid this situation from taking place again, it is important to find the root cause that led to the web break. Luckily your pick up web inspection is there to find the root cause of the web break, which in this case was a tiny fly.

2. Web break caused by insect, defect image from press section.

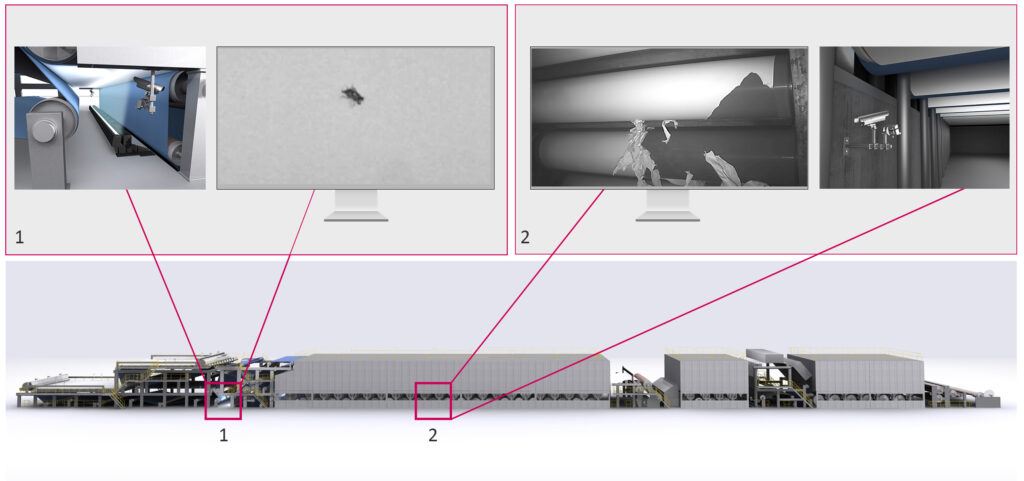

With the traditional web monitoring cameras located on the sides of the paper web in the press section, you can view only those defects, that are located close to the paper edges. Should the defect be in the middle of the web, the web monitoring cameras aren’t your best tools for finding the defect. And even if the defect was located close to the paper web edges, the traditional web monitoring cameras many times are too dirty to provide sharp enough images that would help you.

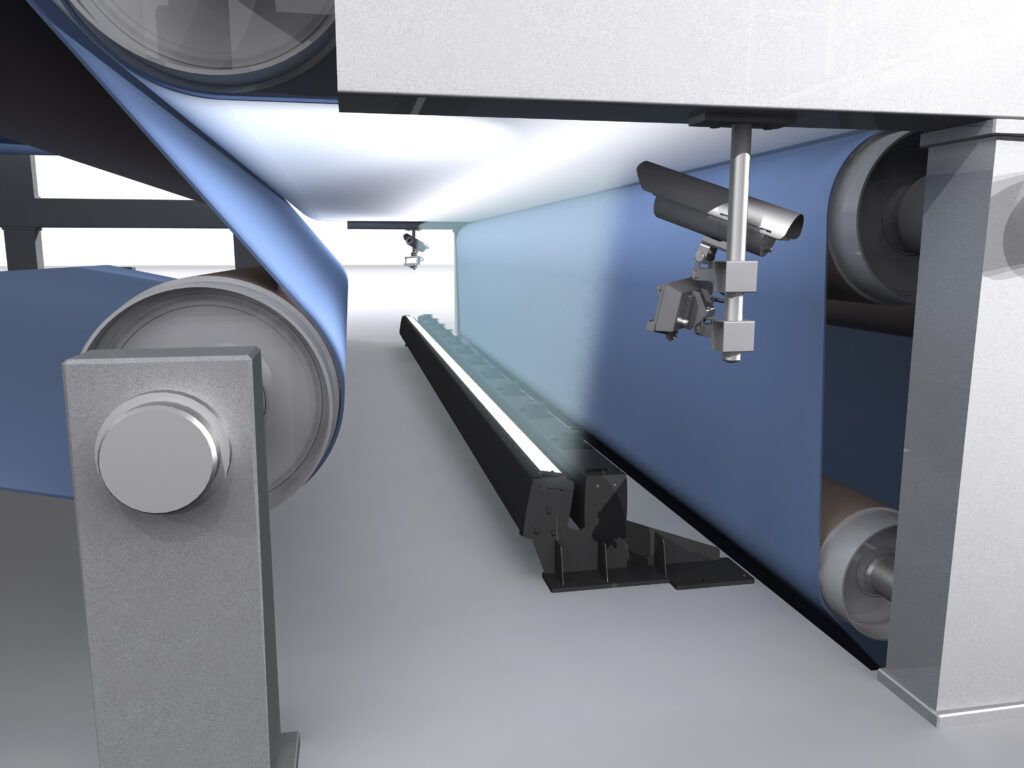

This is why pick-up web inspection is a game-changer. A web inspection frame located in the paper machine’s pick-up point captures the defect images sharply and from the entire width of the paper web. And the images taken are crystal sharp due to the revolutionary Procemex ProClean technology. The pick-up web inspection utilizes pinhole cleaning technology where the air is purged through a 5 mm hole to keep the camera lens continuously clean in a dedicated inspection frame. This technology keeps all the cameras inside the frame clean 24/7 assuring, that not a single spot on the paper web doesn’t get left detected.

But why is the pick-up location such a game changer in defect detection? That is because it makes it possible to limit the root cause search to one paper machine section. If the defect is seen in the images captured by the pick-up web inspection, it gives a clear signal, that the search can be targeted to the forming section. On the contrary, if the defect is seen by the pick-up web inspection, the root cause that caused the paper web break must be situated after the pick-up in the press section.

Based on our experience, the web inspection under pick-up offers a better understanding of where to focus machine cleaning actions in order to improve runnability. This information helps operators save valuable time, and to target the root cause search actions in the right areas. In many cases, the defects are caused by dirt that is built up in the paper machine. This offers also meaningful information from a cleaning point of view. To avoid web breaks taking place again for the same reason, these machine parts need to be cleaned more often or more carefully in the future.

Pick-up Web Inspection System is available for full width & high-speed paper machines. Contact our sales team today to discuss more!

Benefits

- Understand where your machine runnability improvement work focus should be (former vs press)

- Understand better dirt build up patterns over full web width

- Control better wire and felt cleaning

- Verify felt condition on-line

- Control better water removal

- Be sure that the problem taking place at press section is not coming from forming section