Visy Tumut boosts PM efficiency and paper quality

Visy Pulp and Paper Tumut mill is located in southern New South Wales and supplies packaging board for the Australian and overseas markets designed to world-class standards and adopting sustainability objectives in all parts of its operations. Our pulp and paper mill in Tumut produces high-quality kraft paper for both domestic and international markets.

One of the challenges facing operators of modern high speed paper machines is that it is hard to achieve good visibility inside the machine, resulting in less understanding of the reasons for web breaks web defects.

In 2012 Visy Paper reviewed its existing camera systems, which were becoming unreliable and highly maintenance intensive. The analogue camera technology being used was no longer able to meet inpdustry requirements and the requirements of increasingly competitive markets. This, along with the fact that spare parts were no longer readily available, resulted in Visy Paper seeking to replace its existing systems. A tender process began shortly after, with several of the industry’s heavyweights delivering proposals.

After an extensive evaluation process and reference visits, the Procemex TWIN Integrated web monitoring and web inspection system was chosen.

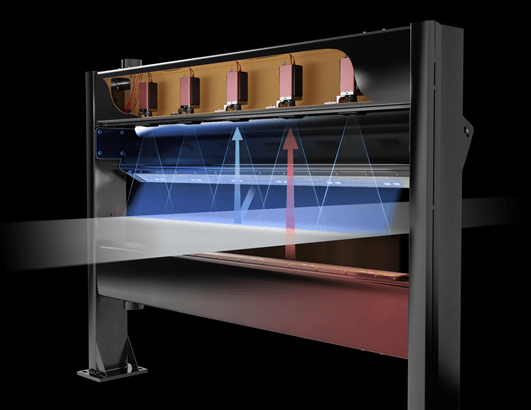

The new Procemex TWIN system delivers machine vision tools to both troubleshoot and monitor web breaks and control paper quality through on-line inspection. So the fully integrated system includes both web break monitoring (WMS) and web inspection (WIS) functions. The system includes Procemex 2.1 MPix HD Flex camera technology and safe LED lighting for both the WMS and WIS.

Visy Pulp and Paper chose the Procemex TWIN system because of its advanced technology, cost-effectiveness and the solid reference checks in Australia, China and Pratt Industries, USA. According to Gary le Roux, Technical Manager, the reasons for the Procemex selection relate to reference site reports of good performance of web monitoring cameras in demanding applications in the paper machine. Reliability coupled with excellent imaging resolution made the selection of the WMS obvious. Moreover, as the mill was intending to install a web inspection system – and with the timing of the project – the TWIN solution made the decision finally clear.

The installation and start up were completed in 2013, involving personnel from Visy Paper, Procemex and UJL (Procemex’s Australian distributor). Visy Paper’s management, Gary le Roux and Carel Kruger, oversaw the installation and implementation process. Procemex’s delivery was very tight after final negotiations, and it was handled with professionalism and excellent after-installation support.

Results even after immediate start-up were astonishing, even though initially there were a few small technical issues. Breaks and image capture were immediately diagnosed and addressed on the machine. The easy navigational operator station was welcomed by operators who now highly rely on the Procemex system.

The Web Inspection system also performed excellently from the time the system was switched on. Defect and small defect detection are exceptional and it also triggers web monitoring cameras revealing the root cause of critical defects. The mill is now working on the integration to the WIS for the ABB Millwide system to transfer defect mapping into roll/set mapping with the objective of grading purposes.

The new system has provided the mill several important benefits. In summary, these can be categorised as:

– improved visibility

– more cameras in demanding areas of the machine

– increased control of paper quality and especially paper surface quality

– rejection of off-spec quality paper

– improved troubleshooting of web breaks / defects

– improved speed and time efficiency on light weight grades

– increased cost-efficiency – less broke and remaking

There are many factors that contribute towards improved visibility inside the paper machine, such as the use of HD cameras, fast frame rates, good lighting and clean camera surfaces. The increase in visibility has shed light on previously unknown elements that cause web breaks and defects. Visy Paper’s Gary le Roux has indicated that about 70% of prior web breaks and defects were due to unknown reasons, as the previous system’s cameras were unreliable. Needless to say, there are now very few web breaks or defects that Visy Paper’s mill operators are unable to explain, improving the mill’s capacity to identify key problem areas.

As for troubleshooting of problems, the phrase “need more data” is aptly met with Procemex, influencing Tumut’s decision making. Mill operators are now able to identify the precise moment and reason for a web break, paving the way for preventative solutions and other improvements in efficiency and cost.

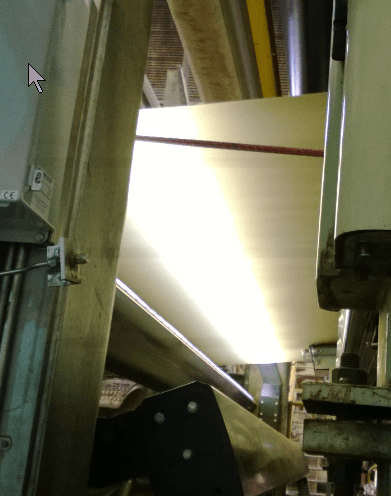

The advantage of having fast frame rates, clear images and accurate camera synchronisation has also made it possible to monitor high speed events out of press and former section locations and especially trim squirts, which was impractical with old camera technology.

Procemex web inspection frame on VP9 with both transmission and reflection illumination

We asked Gary le Roux (from Visy) some additional questions, below are his responses.

How has this technology helped you identify the causes for web breaks? Web defects?

The main improvements have come mostly from the reliability of the cameras and excellent resolution in demanding areas of the wet end. Furthermore, the combination of WIS and WMS (i.e. TWIN system) has enabled the papermaker to detect defects in the sheet which could cause sheet breaks.

What is your opinion about Procemex’s technology?

Since start-up, the WIS and WMS have performed to expectation and produced results consistent with performance guarantees. The picture resolution and imaging is one of the best aspects of the technology.

How does this web inspection technology impact on your clients?

Tumut have very demanding Asian customers requiring very good sheet aesthetic. The web inspection system is a key tool in developing quality controls consistent with these customer expectations. In addition, the WIS will open new grades and market possibilities.

What kind of reaction did you receive from mill operators? Has there been much feedback from them?

Very positive and the uptime of the WMS is very high and all breaks are triggered and diagnosed. The operator station and software is very easy to navigate compared to other systems used in the division.

As mill operators become more familiar with the new camera system, and as more data and information are collected through the use of this technology, management can definitely look forward to further improvements and efficiencies being made.

For more information:

More Success Stories

Nippon Dynawave Packaging: Superior Product Quality and Increased Uptime with Procemex Web Monitoring and Web Inspection System

BillerudKorsnäs Gruvön Mill: “We Are Really Happy to Run Procemex OnePlatform System”

Metsä Board Äänekoski: Higher Customer Satisfaction and Line Efficiency with Procemex Web Monitoring and Inspection System