Nippon Dynawave Packaging: Superior Product Quality and Increased Uptime with Procemex Web Monitoring and Web Inspection System

Nippon Dynawave Packaging, a leading manufacturer of high-quality paperboard for cartons and cups, is dedicated to enhancing the quality of its end products. To achieve this goal, the company decided to invest in a new Web Monitoring and Web Inspection system. In 2020, they installed the Procemex Web Monitoring System, followed by the Procemex Web Inspection System for their L3 product line in 2022. The Procemex 3D web inspection solution ensures that the products from the paper machine are free from defects such as

indents, outdents, wrinkles, and other by-products of the paper-making process.

Finding a Reliable Partner for Superior Defect Detection

Nippon Dynawave Packaging identified the need for a more reliable defect detection system, urging them to search for new solutions to replace their previous setup. They aimed to find a reliable system with superior defect detection capabilities to enhance the detection of wrinkles, indents, and outdents and to improve machine uptime. Quality of system support services and spare part operations were also things they evaluated in their decision-making.

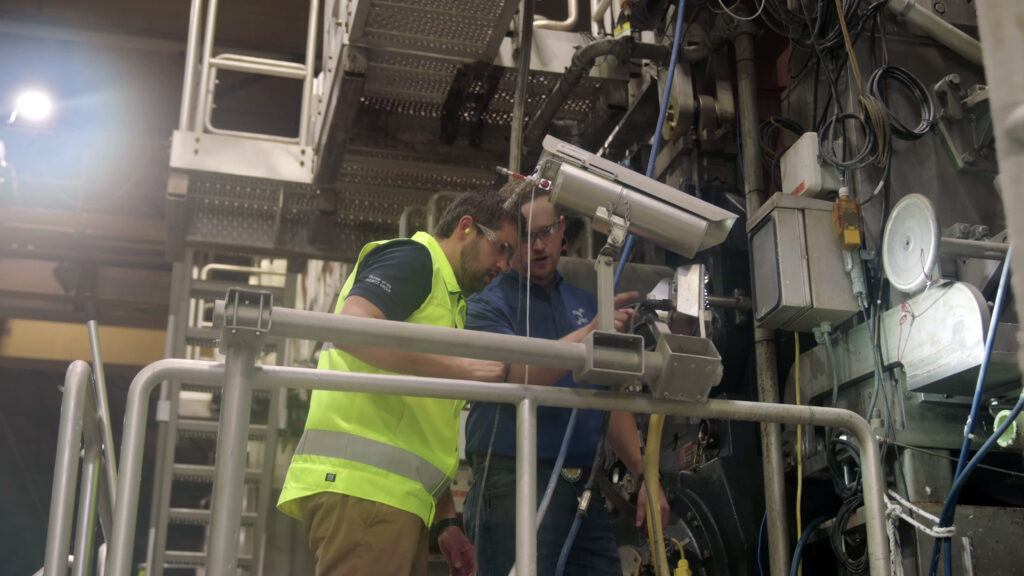

Prior to choosing Procemex as their long-term quality partner, Nippon Dynawave Packaging and Procemex conducted an on-machine trial to demonstrate the capabilities of the 3D web inspection solution. The trial’s image quality and defect detection capabilities were impressive, leading to a decision to fully implement the defect detection system. The 3D Web Inspection solution with Procemex Smart Camera technology was successfully installed and commissioned in 2022, marking the beginning of a successful partnership.

Procemex’s solution stood out during the selection process for the new web monitoring and inspection systems. Its unique features, such as System Virtualization, industry-proven Smart camera technology, smooth System Integration, and reliable Service Operations, made it the best value proposal.

Accurate and Reliable Defect Detection

After the factory approval testing and training, the new system was installed at Nippon Dynawave Packaging’s board mill in Longview, Washington. With over 1,000 systems installed worldwide, Procemex leveraged its extensive experience to ensure quick and efficient system installation.

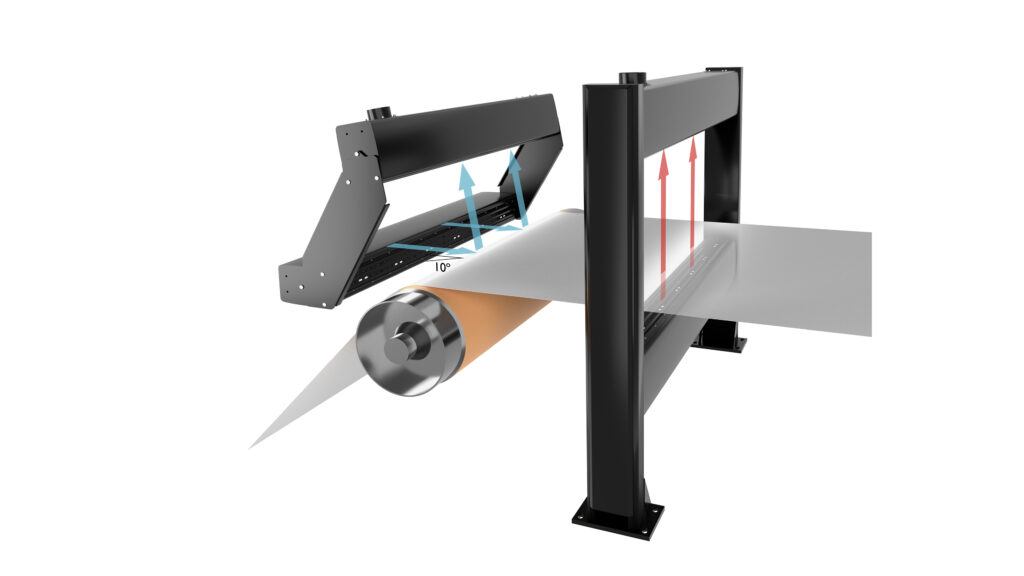

The installed system has High Angle Web Inspection and patented 3D defect detection. The advanced 3D defect detection technology enables the efficient detection of indents, outdents, and wrinkles on coated boards, ensuring that the liquid packaging board produced continues to fulfill end users’ ever-increasing quality requirements.

The fully integrated web monitoring system features today 19 Procemex smart cameras, and powerful Procemex Eco strobe LED lights. Each web monitoring camera position is equipped with the latest Procemex ProClean pinhole technology, ensuring uninterrupted sheet visibility while significantly reducing maintenance requirements.

“Our images remain cleaner and clearer. The Procemex ProClean Pinhole cameras require less cleaning and maintenance. This allows us to place these cameras in environments where other cameras would struggle, all while maintaining excellent image quality,” explains Dustin Bales, the paper machine assistant manager of L3.

Increased efficiency in Winder Operations

The implementation of the Procemex OnePlatform System has significantly enhanced the efficiency of winder operations at Nippon Dynawave Packaging. The Procemex OnePlatform system provides operators with a clear defect map, complete with exact coordinates and the type of defects accurately marked. Easy access to sharp and clear defect images gives operators a clear understanding of the nature of the defect, enabling them to make quick and informed decisions. As a result, the winder operations have become more efficient, leading to a noticeable increase in quality and productivity.

Based on accurate knowledge of the machine’s directional and cross-directional defect location, Nippon Dynawave Packaging’s winder operators can make educated decisions about whether to run the winder at full speed, slow it down, crawl, or stop the winder to patch the defect. These decisions can be made either manually by the operators or the process can be automated.

“We are very pleased with the system operation. When we tell it to stop, the winder stops exactly at the position where the defect is located. Although I can’t provide a specific metric to quantify the increased efficiency it has brought to our process, I know it is significantly higher,” Aaron Harman, the Process Manager of Nippon Dynawave Packaging’s Extruder Department, comments.

One comprehensive system for complete web monitoring and inspection

The Procemex OnePlatform solution offers a single, comprehensive system for complete web monitoring and inspection. Designed for seamless operation between web monitoring and inspection, it combines user-friendly functionality with advanced system virtualization, enabling operators to resolve issues efficiently. This unified approach enhances machine uptime and boosts overall production efficiency, ensuring smooth daily operations.

“The Procemex OnePlatform system is very user-friendly. I can access the server remotely from my laptop, troubleshoot things, and help guide operators and foremen to resolve issues faster.

Being able to select a synchronized camera view and not having to scroll through all the video footage. It helps to reduce the time to find what caused the web break,” says Dustin Bales.

Reliable Support and Service Operations

Nippon Dynawave Packaging emphasized the need for reliable support and service from the start of the project, highlighting its impact on system uptime. The comprehensive service agreement with Procemex ensures continuous 24/7 technical support and regular on-site and remote maintenance to keep the system performing at the highest level. Procemex’s commitment to responsive and proactive service has not only met but exceeded these expectations, ensuring smooth and uninterrupted operations.

“The Procemex OnePlatform System has now been running for almost two years. And they continue to support us every day. Procemex did not just come and sell us something and disappear; they have been with us every day when we have had concerns or questions, and we have been able to solve them very quickly. So far, everything has been working really well,” says Perry Brandenburg, Paper Machine Manager at Nippon Dynawave Packaging.

You might also be interested in these

Success Story: Metsä Board Äänekoski

Higher Customer Satisfaction and Line Efficiency with Procemex Web Monitoring and Inspection System

Measurement Geometries

Procemex has developed a variety of measurement geometries for detecting and inspecting different types of paper defects.

ProClean Pinhole Camera

Procemex ProClean Pinhole Cameras stay clean even in the harshest conditions