Improve Pulp Production

Process and Reduce Customer Claims with Procemex Dirt Count Analyzer

The Procemex® Dirt Count Analyzer is an online measurement system. It detects and classifies dirt and shives according to ISO and TAPPI standards providing both dirt count per square meter and dirt area per square meter (ppm).

Dirt that does not qualify as dirt according to the standard is rejected from the calculation. Beyond standards, some objects like metal wires, oil and special particles relating to different raw materials are detected and classified based on their shape.

With Procemex Dirt Count Analyzer you can improve your pulp production

process and reduce customer claims arising from shives and dirt in pulp.

With visual, real-life image you can attain and analyze information fast and make more accurate decisions. The most cutting-edge advantage is, that the system enables an early discovery of defects. This allows the operators to take fast actions, which result in more efficient production and improved quality.

Compare Procemex® Dirt Count Analyzer and conventional systems

How the Dirt Count Analyzing Process Works?

The Procemex® Pulp Dirt Count Analyzer is an online measurement system. Dirt detector classifies pulp dirt and shives according to ISO and TAPPI standards providing both dirt count per square meter and dirt area per square meter (ppm).

Dirt that does not qualify a dirt according to the standard is rejected from the calculation. Beyond standards, some objects like metal wires, oil and special particles relating to different raw materials are detected and classified based on their shape.

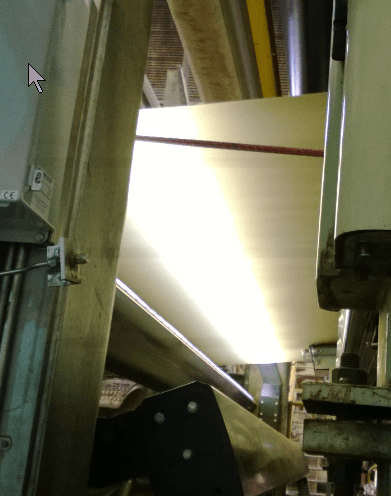

The Procemex® Dirt Count Analyzer is measuring in transmission with strobe LED lights with the camera resolution of 0.1 x 0.1 mm to meet TAPPI/ISO standards. You can choose between full CD/MD coverage or one camera per bale or just few measurement points.

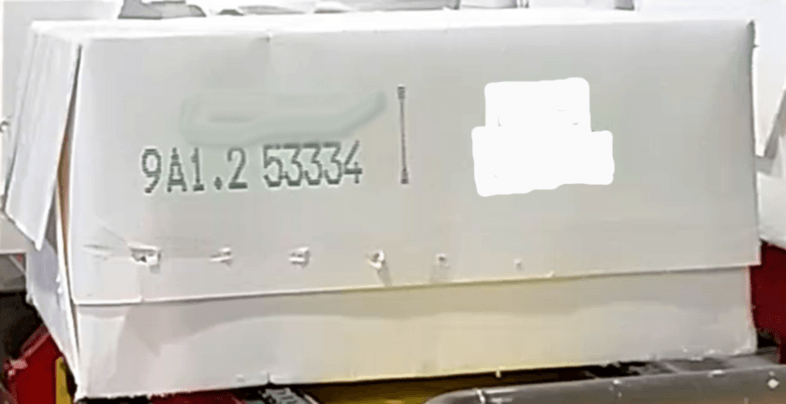

The Procemex® Dirt Count Analyzer detects dirt in real time and stores every defect individually into the system database. The dirt detector keeps operators up to date with the amount of defect per set, per bale and per time. The amount of dirt in each bale is indicated both in real time values and with color coding. Operators can monitor real time dirt count trends indicating process changes and enable fast corrective reaction.

The dirt detector values are transferred to the customer quality data management and bale tracking systems providing an easy access to any of the historical information.