Integrated Vision System Procemex® OnePlatform

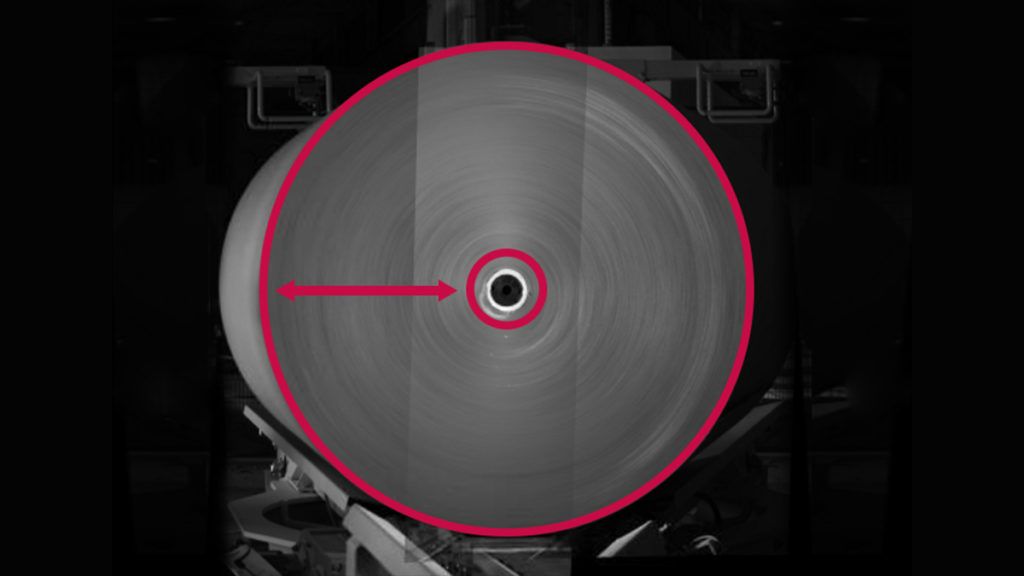

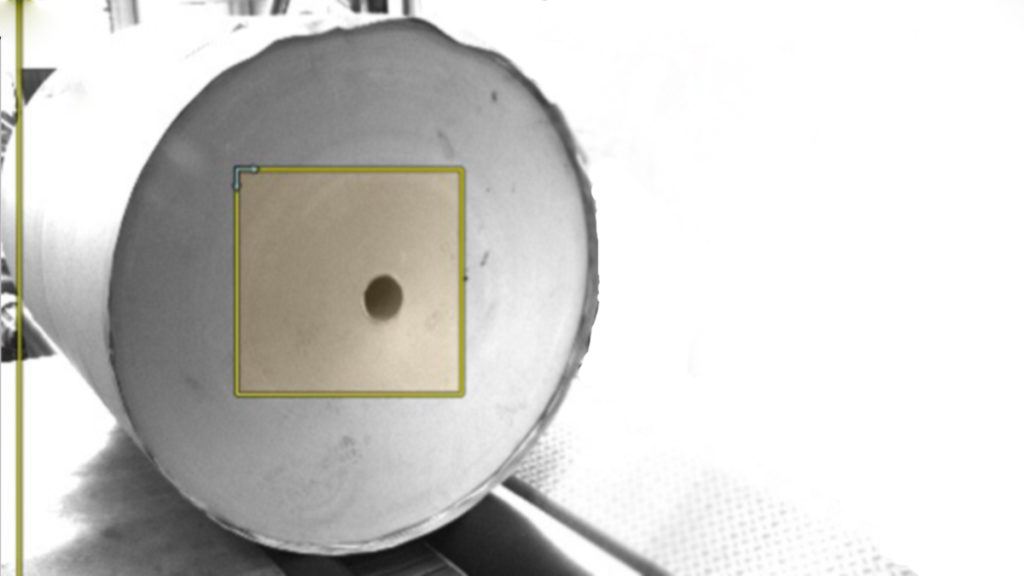

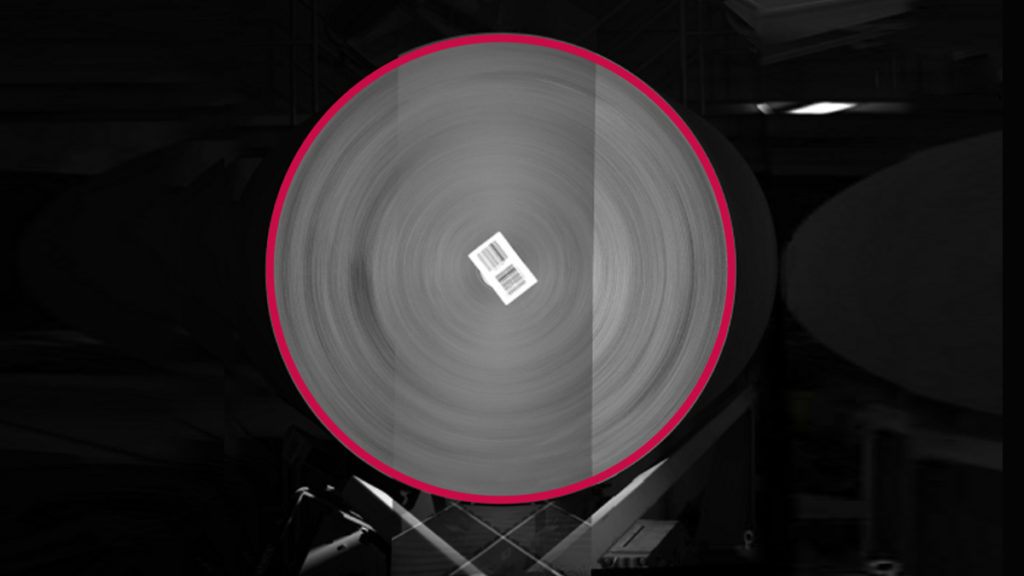

Procemex OnePlatform is an Integrated Paper Web Break Monitoring and Paper Web Inspection system, which seamlessly combines Web Monitoring and Web Inspection system functionalities together making it easy for the operators to understand the interrelations of the real root causes for paper defects and web breaks created in the dryers, press and forming section. Automatic winder target control (ATC) enable running the winder with optimal speed leading to big savings in materials and energy.

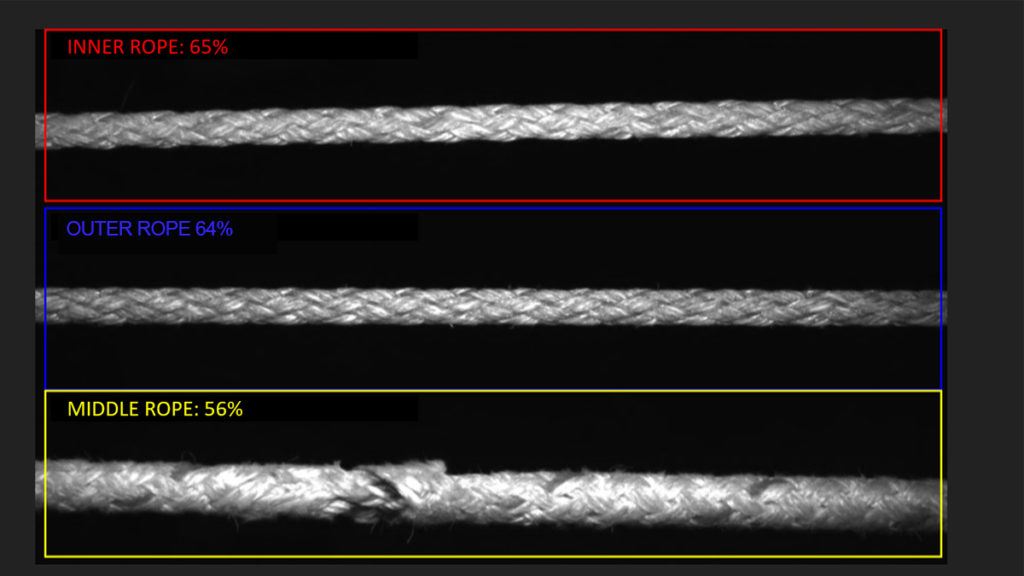

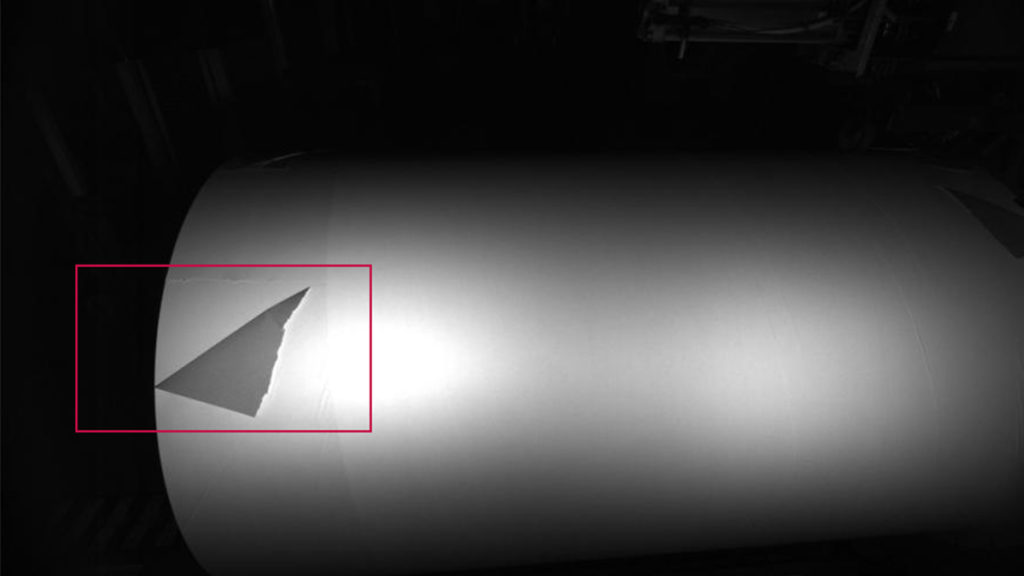

Accurate real time images of paper web defects are detected with advanced ProClean camera technology and smart led lighting solutions. Unique system architecture processes image data in the cameras, assuring the data gets smoothly and fast transferred to the system without and interruptions. Wide range of AI-enhanced analyzing applications in the different production phases helps the operators in smart decision making.

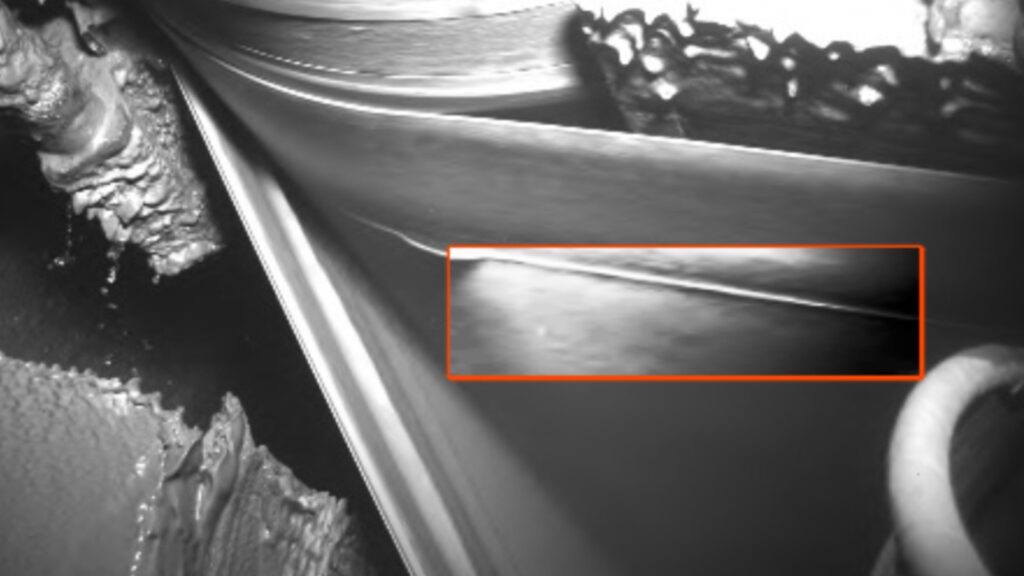

Web Monitoring

Web Monitoring cameras along the production line provide additional eyes for the operators and clarify the root causes for a web break.

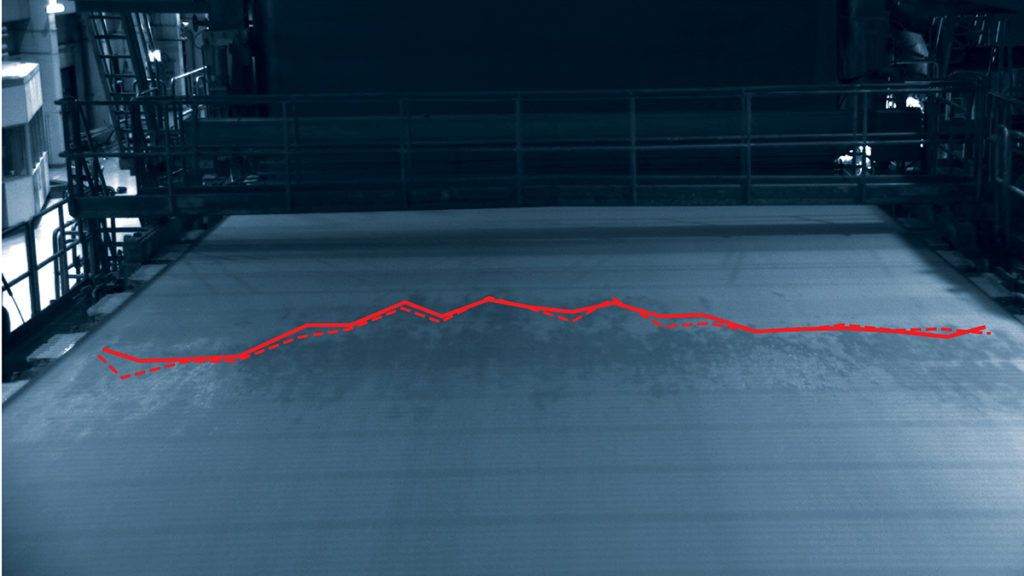

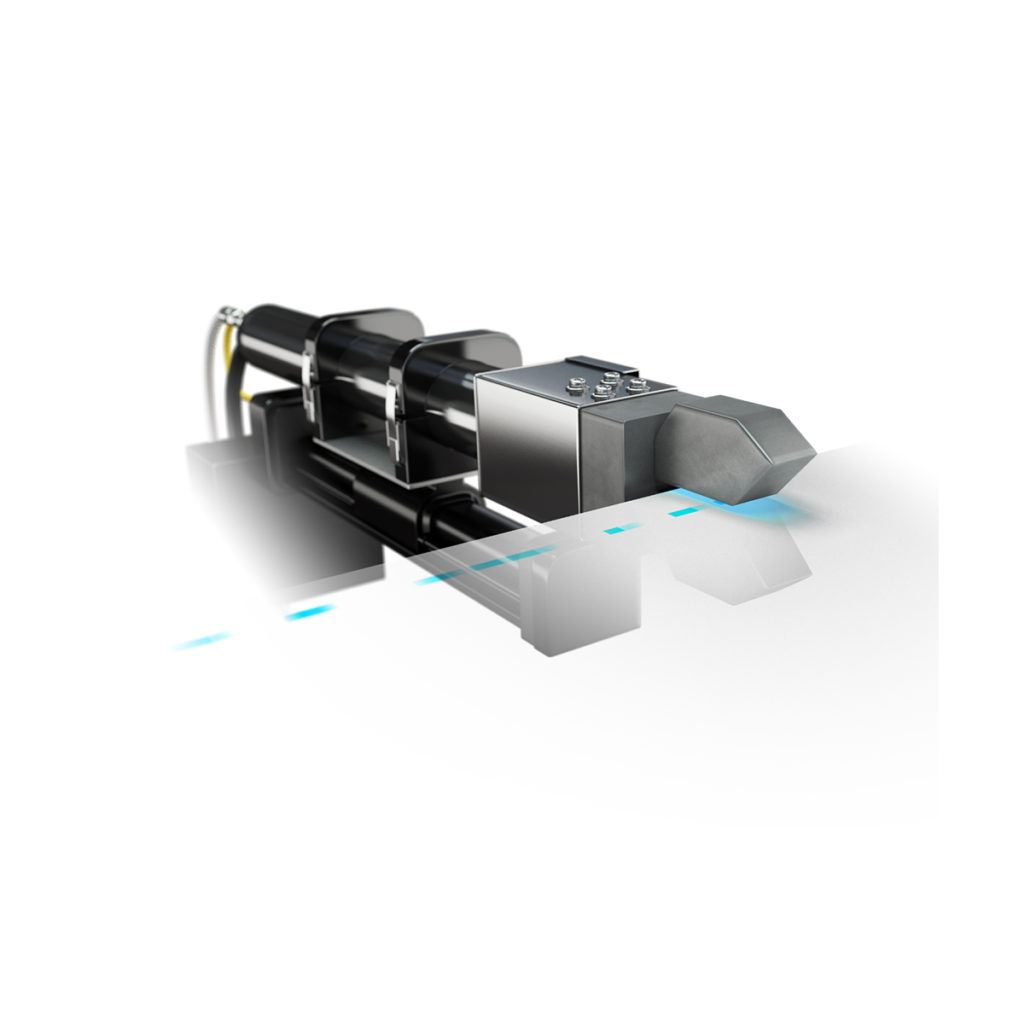

Printability Measurement

Valuable data about the surface roughness with TOPO-printability measurement

Vision Applications for Paper & Board Industry

A comprehensive range of AI-enhanced analysis applications take web inspection and web monitoring to a completely new level. They improve production flow and product quality, manufacturing efficiency and operator safety.

Products

Success Stories

Nippon Dynawave Packaging: Superior Product Quality and Increased Uptime with Procemex Web Monitoring and Web Inspection System

BillerudKorsnäs Gruvön Mill: “We Are Really Happy to Run Procemex OnePlatform System”

Metsä Board Äänekoski: Higher Customer Satisfaction and Line Efficiency with Procemex Web Monitoring and Inspection System