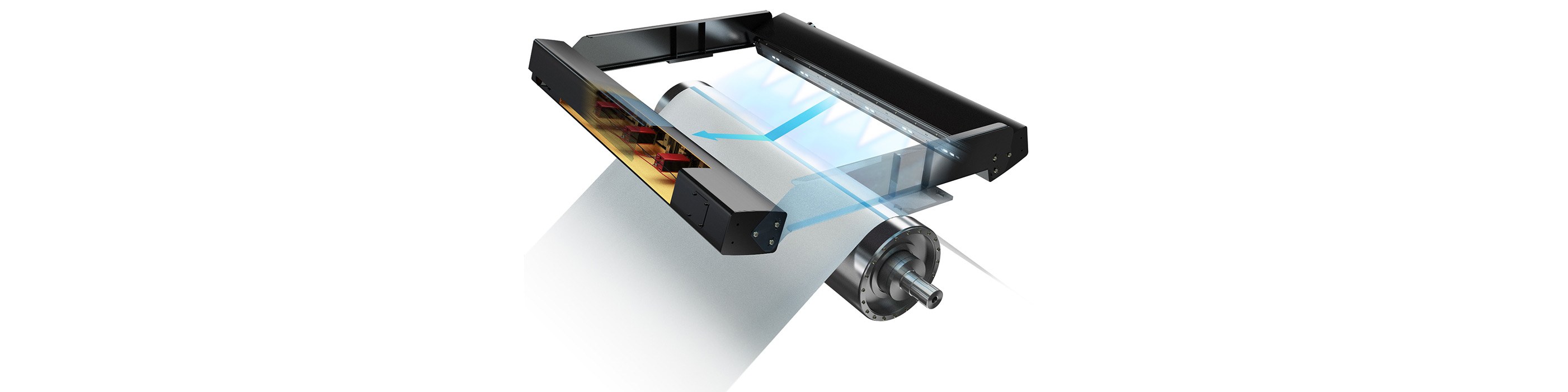

Low Angle Web Inspection

One-profile measurement geometry for detecting and classifying coated product surface defects

The low angle inspection geometry uses typically 15-20 degree camera angle and 15-20 degree illumination angle to provide a mirror reflection from the paper surface. This enables to detect very small coating defects, such as streaks or coating skips. It should be however noted, that low angle reflection is not replacing a high angle reflection due to the nature of the mirror reflection. It can not detect even very visible spots, if they are over-coated.