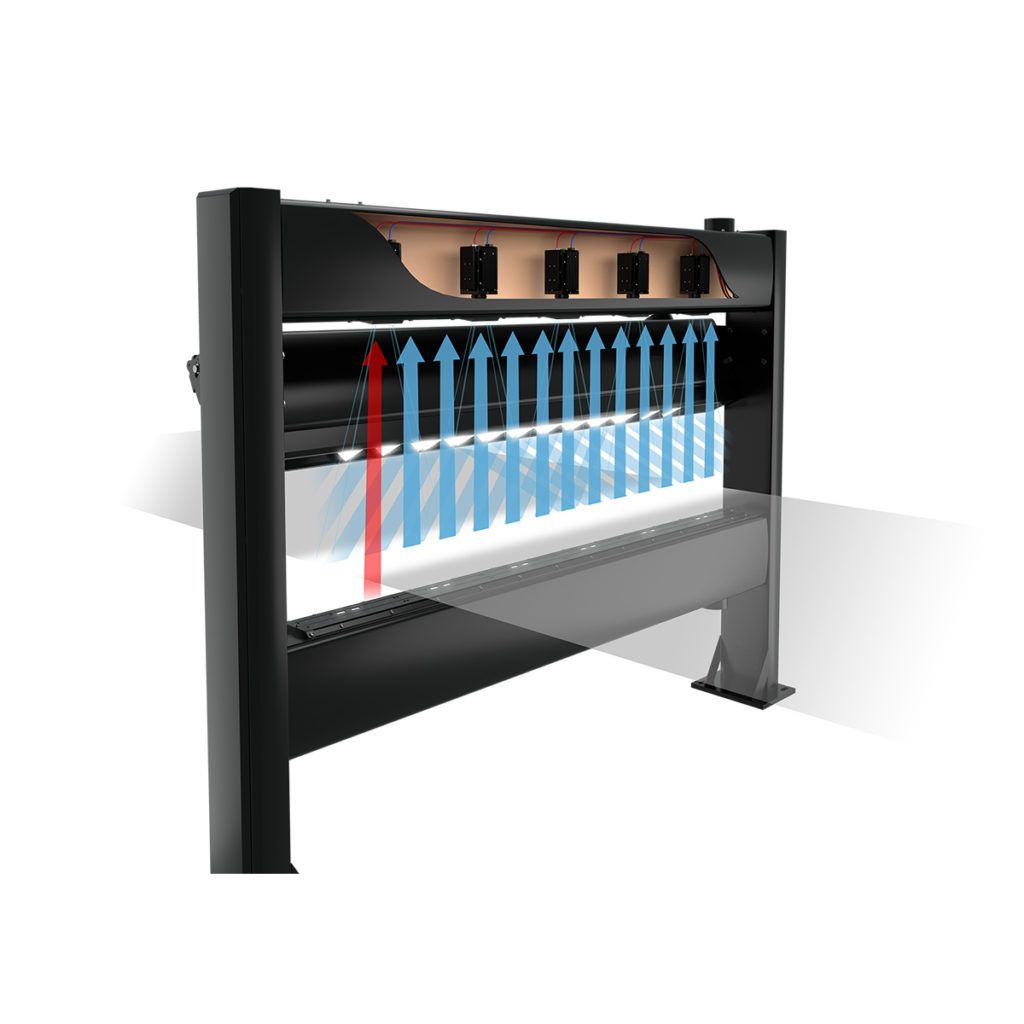

Crossed (30 degree) Side Light Web Inspection

Two-profile measurement geometry for detecting and classifying all defects focusing on surface wrinkles and de-formation

Crossed side light geometry is often combined with transmission measurement geometry. This geometry enables to detect very small wrinkles and surface de-formation by creating a shadow from side direction. The illumination angle is very low in order to be able to provide adequate shadow effect.

As the light frame shifts in side direction approximately 700 mm due to light frame distance to the paper web, the crossed side light was invented and patented in order to illuminate front side from back side and vice versa. This enables to position frames within machine columns and there is no need to find a place for a light frame sticking 1000 mm out from machine frame.

Even though front side and back side illumination pulse takes place subsequently, they still use only one data processing profile. Crossed illumination solution also eliminates a problem to illuminate over (through) curly paper edge as it illuminates from middle towards paper edges.