Color Marking

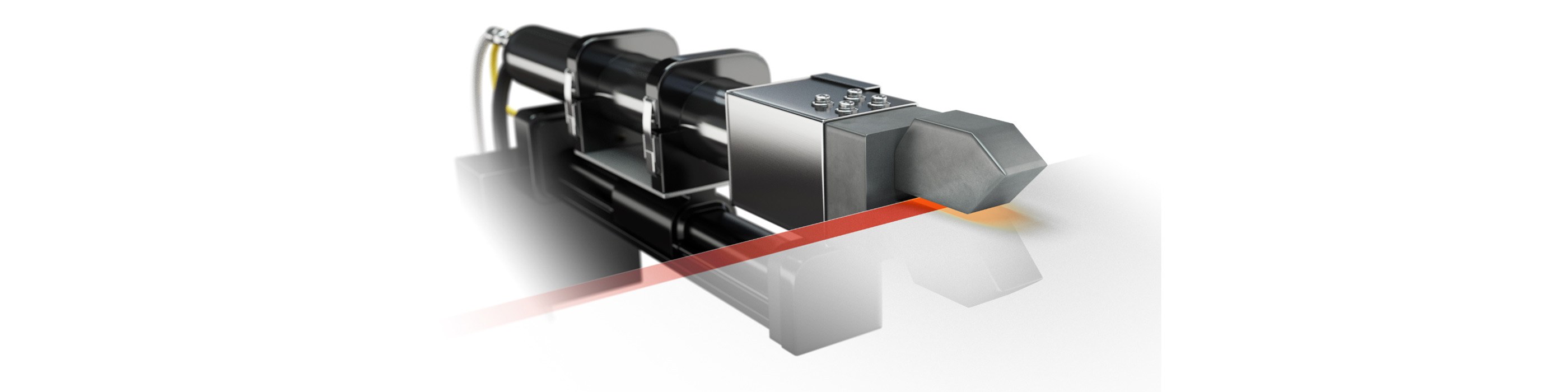

Color Marking identifies defects in your product with color marking.

Defect mark enables manual off-spec rejection

Certain defects in a web will cause problems in subsequent processes. Also, for quality purposes, these defects must be identified and removed prior to shipping to your customers. A Defect Marker places a colored or invisible mark on the web at the machine direction location of the defect.

Marked defects warn downstream operators to take preventative actions to avoid downtime and ensure that your customers receive only your best product.

High precision distance encoding and reading is applied in different manufacturing steps to enable accurate positioning of defects on defect map and to enable automated or manual off-spec paper rejection

- Enables defect removal process

- Integrated with Procemex software

- Real-time – smart WIS cameras triggers defect marker

- Features automatic self-cleaning

- Features automatic edge position recognition

Key Features

- Enables to produce trouble-free product

- Increases production line throughput

- Real-time marking – WIS Cameraa directly triggers marker