Code Reading / Code Verification

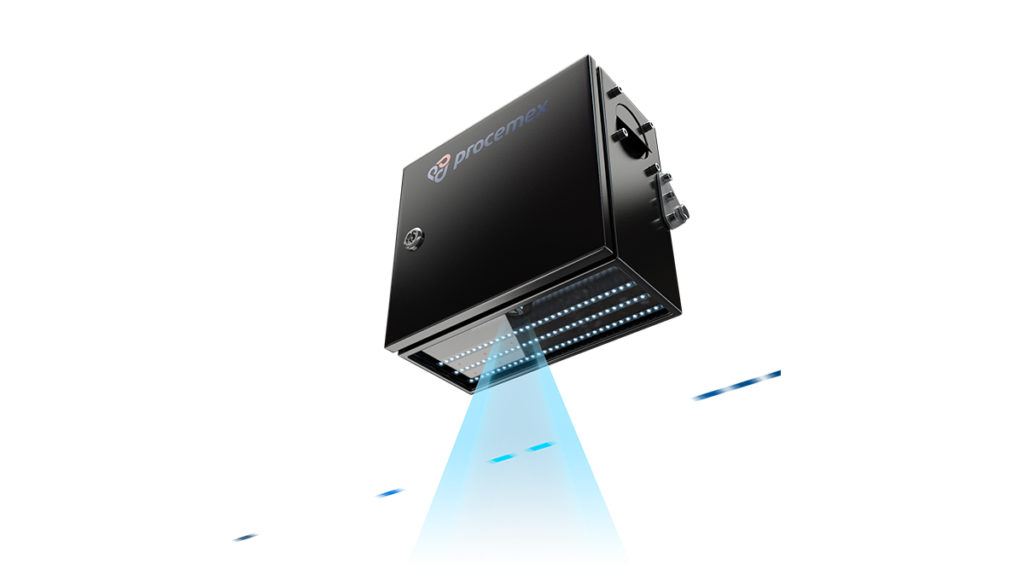

High-precision smart cameras with LED strobe light read codes on winders running up to 3000 m/min (9800 ft/min). Code reading is synchronizing different manufacturing steps with each other.

Code marks placed on the web in an upstream process usually indicate a warning to a downstream operator. With a mark reader the marks can be automatically detected and defect map can be synchronized on spot. A mark reader is closing the loop on your defect detection and removal program.

Key benefits

- Helps close-the-loop on the defect removal process automatically.

- Saves time; no operator is needed to search for defects.

- Locates defects quickly and efficiently

- Codes can pass critical roll information to downstream processes

- Defect removal process is automated

- Procemex software includes built-in error checking

- Features automatic edge position recognition

- Provides absolute sheet position regardless of slab-off and shrinkage

- Fast code reader cameras enable small code size and low ink usage

- Enables automated re-reeler and winder stop features

- Increases production line throughput

- Helps close-the-loop on the defect removal process automatically.

- Saves time; no operator is needed to search for defects.

- Locates defects quickly and efficiently

- Built-in error checking ensures perfect availability: The code reader camera has special software built-in for checking errors and making smart decisions

- Compact size: Compact size and low weight make this unit preferred solution for existing machines with limited space

- Powerful strobe illumination enables successful high accuracy code reading with small mark size on fastest machines in the world