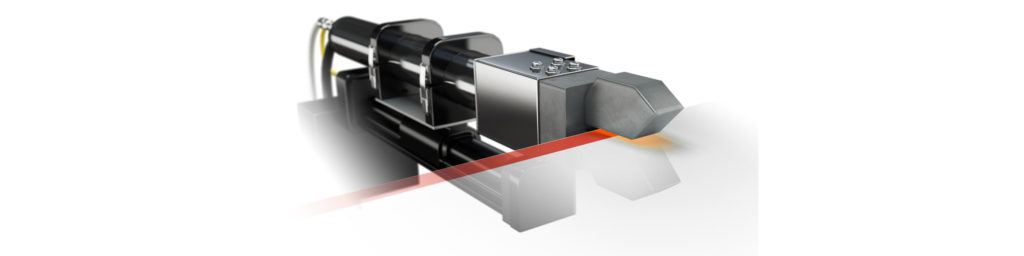

Code Marking

Paper length is ”barcoded” at the edge of paper sheet with high precision and optional mark verification.

Absolute length code mark enables transfer of inspection data between different manufacturing steps

Sometimes it is necessary to encode intelligent information into a moving web at high speeds. The most common information encoded is that of incrementing length or footage. Other information that can be encoded relates to roll-ID or lot numbers. The encoded information entered at high speeds is “read” and decoded downstream and used for process control.

High precision distance encoding and reading is applied in different manufacturing steps to enable accurate positioning of defects on defect map and to enable automated or manual off-spec paper rejection

- Codes can pass critical roll information to downstream processes

- Defect removal process is automated

- Procemex software includes built-in error checking

- Features automatic self-cleaning

- Features automatic edge position recognition

- Code verification carried out with a separate camera & light unit after marking position

Key Features

- Enables automated re-reeler and winder stop features

- Increases production line throughput

- Code verification ensures perfect availability

- Provides absolute sheet position regradless of slab-off and shrinkage

- Fast code reader cameras enable small code size and low ink usage

- Enables automated re-reeler and winder stop features

- Successful encoding up to 2000/m/min , 6500 ft/min

- Small mark size and ink usage keep environment clean