ProClean Camera technology keeps cameras clean

The challenge to keep the web break cameras clean is an everyday reality in all board and paper mills. Dirt in the camera’s protection window make the images dark and fuzzy. The new Procemex ProClean pinhole technology guarantees that cameras stay clean 24/7 and provide sharp and clear images for operators to monitor paper defects and root causes of web breaks.

Web monitoring cameras are kept clean under harsh wet end conditions with the aid of instrument air flow. The air is blown through a 5 mm hole in front of the camera housing. As the air flow speeds up when passing the pinhole it forms a strong protection against dirt and prevents water and dirt entering the housing. The housing has no protection window that could get dirty or wear out. The camera is equipped with a dedicated pinhole zoom lens capable of viewing through a very small hole.

As most of the cameras are located in the forming and press section, it is clear that keeping cameras and lights clean in a harsh environment is important. This is also a foundation for coming image analysis and AI applications.

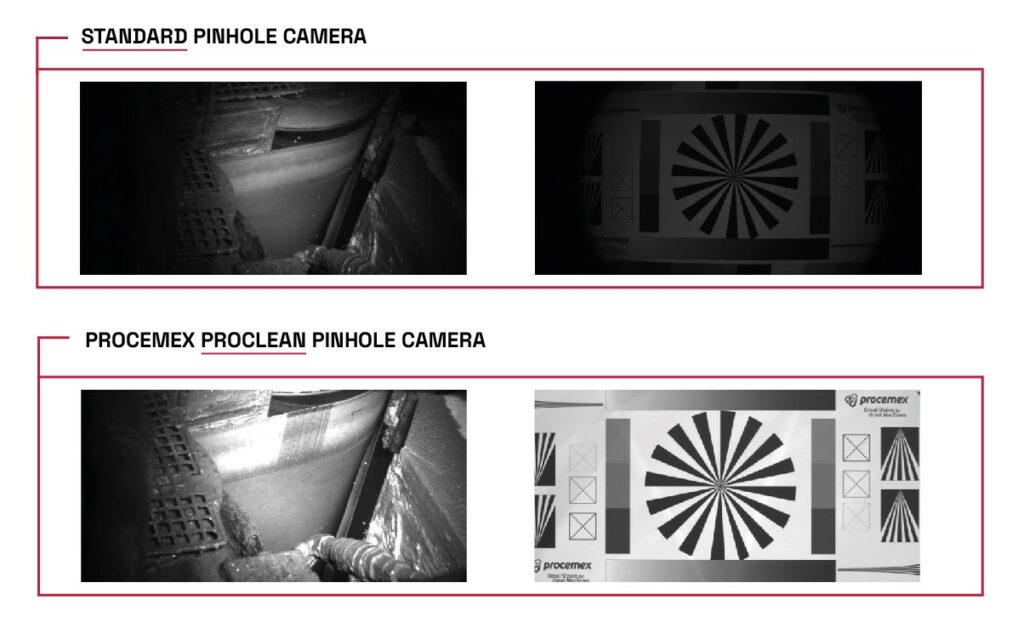

Standard Pinhole camera vs. Procemex ProClean Camera

A standard pinhole camera with 1/2.000 sec or lower shutter speed can’t stop paper movement properly and lacks light especially in corners of the imaging area. Procemex ProClean pinhole camera, with 1/8.000 sec shutter speed stops paper movement and has even illumination across the imaging area resulting to crystal clear images.

Procemex ProClean Pinhole camera is equipped with a dedicated pinhole zoom lens capable of viewing through a small 5mm hole. The lense is a unique purpose-built component designed to utilize available illumination better reaching 5-10 times higher shutter speeds over standard pinhole lenses.

Higher shutter speed stops fast moving paper web better resulting to crystal clear image quality.

The benefits of ProClean Pinhole Camera are trouble-free operation, low air consumption, 100% continuous visibility and the simplicity of the concept. There are no moving or wearing parts such as wipers, electronics or controlling components.

Continuous air flow enables pinhole cameras to film undisturbed 100% over the time without washing cycles or wiper movements causing blind times during the cleaning process.

ProClean Pinhole Cameras can be used in all paper machine locations from headbox to the reel

Traditionally standard pinhole cameras have been used by so far only in the most difficult environment, such as paper machine wet end locations. The reason for not using them in every position, has been lower image quality than with the cameras equipped with standard lens and protection window. This has now changed. The traditional pinhole camera bottlenecks such as low resolution, low pinhole light sensitivity resulting to lower shutter speeds and in capability to stop fast moving paper web and blurry images and pinhole images being sharp in the middle and dark and fuzzy in edge areas are not relevant any more! Procemex ProClean Pinhole Cameras can be used in all paper machine locations from headbox to the reel.

Benefits

- No manual cleaning needed.

- ProClean Pinhole Cameras can be used in all paper machine locations from headbox to the reel.

- Existing standard housing can be converted into pinhole housing by changing the small nose piece.

- Low air consumption. No moving or wearing parts.

- Camera Resolution 2- 12Mpix. Always 100% visibility. Clear images from edge to edge. Procemex Smart Cameras are not limited by the network capability, as the camera processes data inside its own shell.

- 5-10 times higher shutter speeds over standard pinhole lenses. Clear images without blur caused by web movement.

Procemex ProClean Pinhole Camera’s Features

- Superior Resolution: from 2.1 and 12 MPix web monitoring resolution (with full 50/60 frames per second).

- Horizontal resolution up to 4096 pixels, vertical resolution 3072 pixels available with pinhole camera cleaning solution (filming through 5 mm hole with air purge)

- Pinhole images are sharp also at edge areas and image corners

- 5-10 times faster shutter speeds eliminate image motion blur (1/10.000-1/30.000 s)

- Extended digital zooming

- Possibility to window resolution down to increase image frame rate

- FIFO RAM memory buffer inside the camera´s own shell

- Read more about Procemex Crystal ProClean Pinhole Camera.

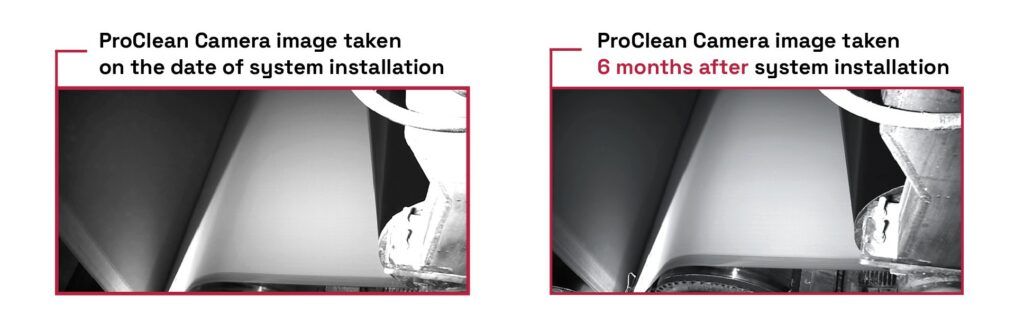

How Procemex ProClean Pinhole camera images looked after six months from installation

I have been working in the paper industry for several years in Indonesia. During this time, I have traveled across different areas in Indonesia and visited dozens of paper mills. It has been very exciting to see with my own eyes the extreme conditions, where the paper web monitoring cameras must perform optimally, to provide accurate images to mill operators, enabling them to enhance production line efficiency and recognize paper web defects accurately and on time.

I thought it would be interesting to take before and after images with Procemex ProClean Pinhole Cameras, and see, how they perform and maintain the image quality in harsh paper mill conditions, six months after installation. Read More

Web Monitoring

Web Monitoring cameras along the production line provide additional eyes for the operators and clarify the root causes for a web break.

Smart Cameras

Extensive range of Smart Cameras. Image analysis takes place inside of the Smart Cameras.

Success Story

Metsä Board Äänekoski: Higher Customer Satisfaction and Line Efficiency with Procemex Web Monitoring and Inspection System