Choosing the right web inspection and monitoring system

In today’s high-speed paper and board production, efficient defect detection and web break root cause analysis are critical for ensuring quality and minimizing waste. If your current web inspection and web monitoring system is not meeting expectations, it may be time to explore new solutions that offer better accuracy, reliability, and machine uptime.

What are the signs that you need a new web monitoring and web inspection system?

- Frequent false alarms or missed defects

- Challenges in keeping cameras clean

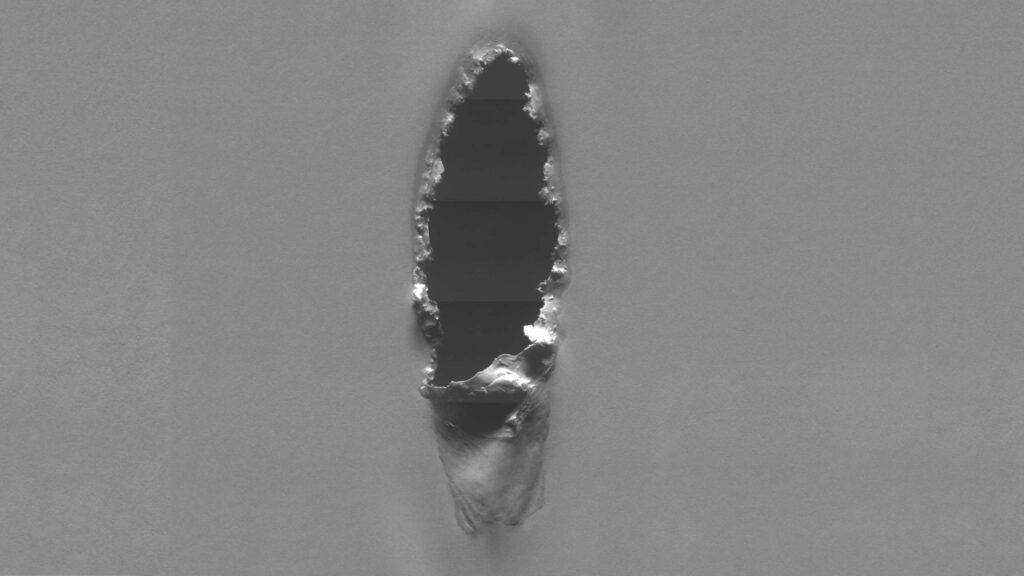

- Limited detection accuracy for fine cracks, holes, or coating issues

- Poor performance at high machine speeds

- Challenges in finding the root causes for web breaks quickly

- Outdated software lacking AI-driven analysis and detection

Key Features to Look for in a Modern Web Inspection and Monitoring System

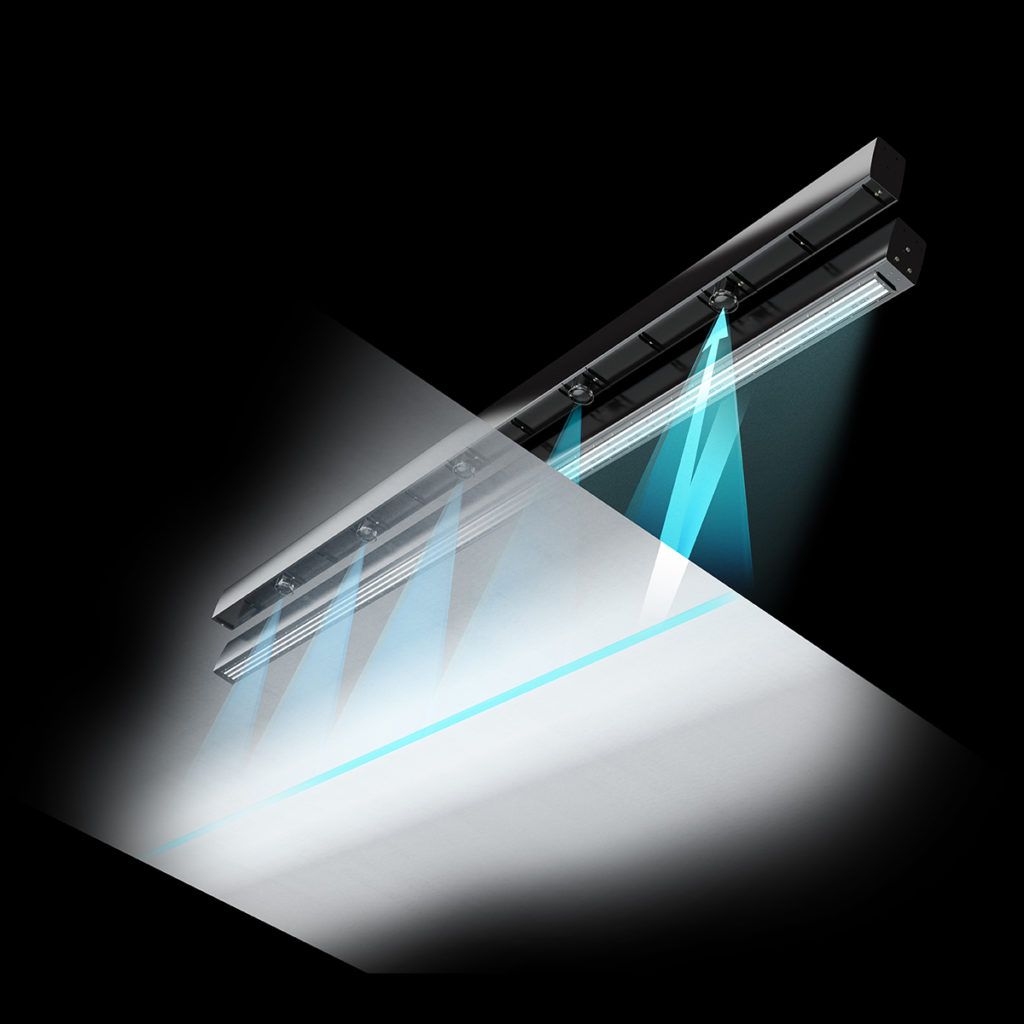

| High-Resolution Smart Cameras | Capture even the very finest defects at full production speed. |

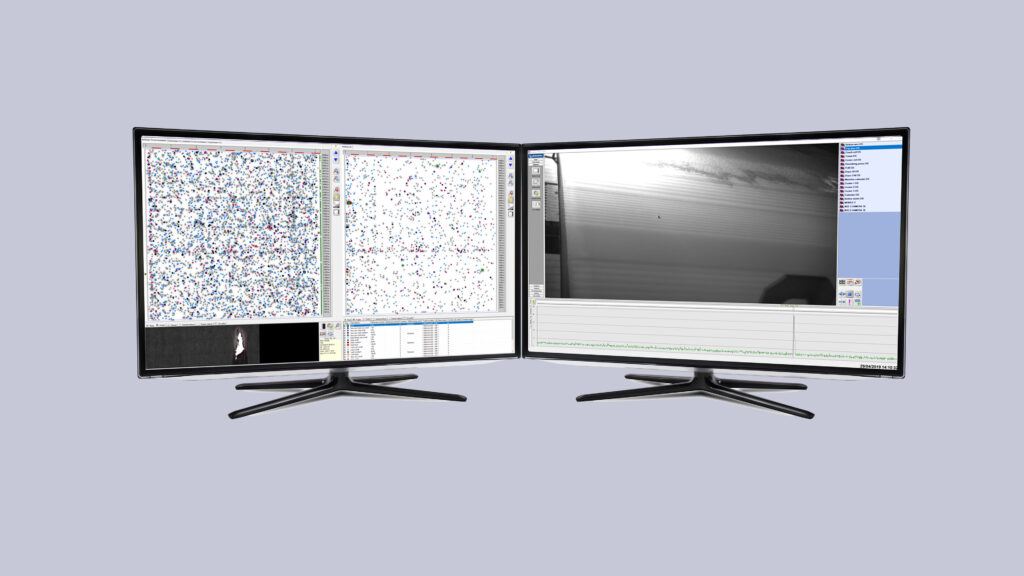

| AI-Powered Analysis tools | The system has capabilities to do much more than defect monitoring and web inspection. AI-enhanced tools offer effective tools for analysing threading rope condition, roll surface defects, etc. |

| Integrated Web Monitoring & Inspection | A single, unified system to track quality and detect breaks. |

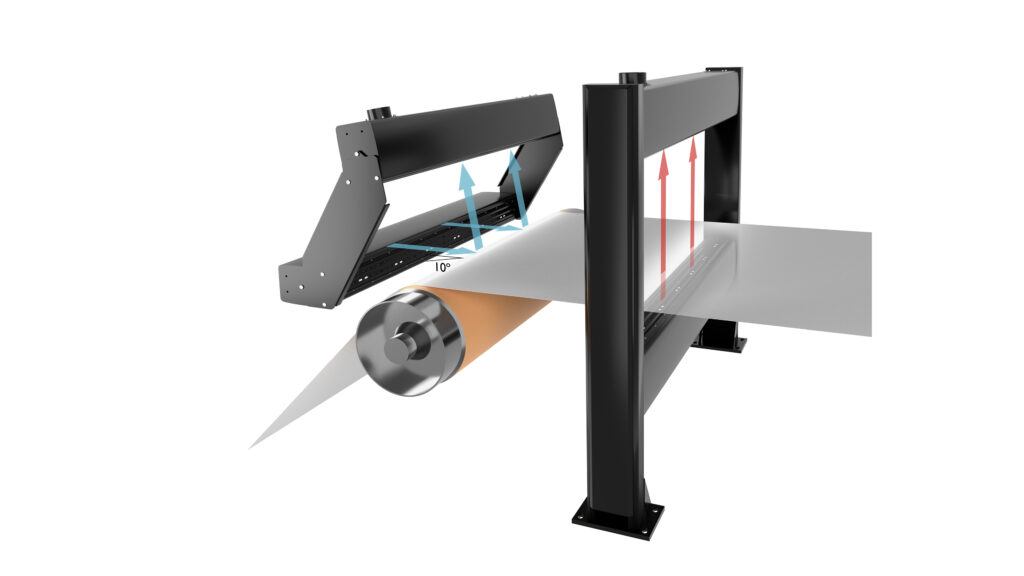

| Cameras that stay clean | Ensures cameras stay clean for accurate defect monitoring. |

| Remote Access & Predictive Maintenance | Minimize downtime with real-time system monitoring. Proactive service operations keep your system running at the optimal level. Every day. |

Why Procemex?

Procemex is the leading manufacturer of web inspection and monitoring solutions for the pulp and paper industry. Procemex One Platform system integrates high-speed web monitoring cameras with advanced defect detection, helping mills improve quality, reduce waste, and maximize machine uptime.

Ready to upgrade your web inspection and monitoring system? Contact us today to learn how Procemex can optimize your production with industry-leading technology.